Hello, welcome to Cangzhou Ever-Power Co., Ltd.!

- Tyre coupling

- Flexible log-off coupling

- Flange coupling

- Universal coupling

- Roller sprocket coupling

- Drum type gear coupling

- Star elastic coupling

- Plum elastic coupling

- Oldham coupling

- Clamping coupling

- With brake disc coupling

- Snake-shaped yellow coupling

- Diaphragm coupling

- Nylon internal gear coupling

Contact Us

your present location:HOME > Diaphragm coupling > Roller sprocket coupling >

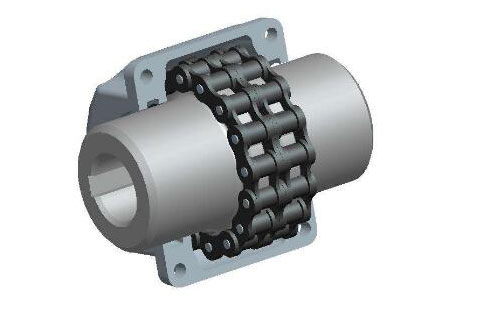

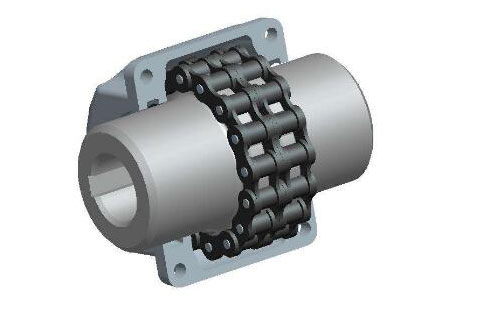

Roller sprocket coupling

GL sprocket coupling

Time: 2019-01-11 10:03 Author: admin Click:

Detailed description of GL roller chain coupling:

The roller chain coupling consists of a pair of sprockets with sleeves, which are connected between the two sprocket teeth by two rows of roller chains, which are mainly used to transfer large torque between large diameter shafts.

GL-type roller chain coupling AUTOCAD renderings (GB6069-2002 instead of GB6069-86) Features: The chain coupling uses a common chain, which is combined with two teeth at the same time.

The same parallel sprocket meshes, and the main difference between chain couplings of different structural types is the use of different chains. The common ones are double-row roller chain couplings, single-row roller chain couplings, toothed chain couplings, Nylon chain coupling, etc.The performance of double-row roller chain couplings is better than other structural types of couplings, and is widely used at home and abroad. my country has also formulated standards.

A detailed description

The GL type roller chain coupling uses a common chain to mesh with two parallel sprockets with the same number of teeth. The main difference between chain couplings of different structure types is the use of different chains. Common ones are double-row roller chains. Couplings, single-row roller chain couplings, toothed chain couplings, nylon chain couplings, etc.The performance of double-row roller chain couplings is better than that of other structural types of couplings, and is widely used at home and abroad, and our country has also formulated it as a standard.

The GL type roller chain coupling has a simple structure (composed of four pieces), convenient assembly and disassembly, no need to move the connected two shafts during disassembly, compact size, light weight, certain compensation capabilities, and low requirements for installation accuracy. Reliable work, longer life, lower cost, etc.

It can be used for shafting transmission of textile, agricultural machinery, lifting and transportation, engineering, mining, light industry, chemical industry and other machinery. It is suitable for high temperature, humidity and dusty working conditions. It is not suitable for high speed, severe impact load and transmission of axial force. In the case of low pressure, the roller chain coupling should work under the conditions of good lubrication and a protective cover.

Advantages and disadvantages of GL roller chain coupling:

The GL roller chain coupling transmits movement and power in a long distance.It can work under low speed, heavy load and high temperature conditions and dusty conditions.It can ensure the accurate transmission ratio, the transmission power is large, and the force acting on the shaft is small.High transmission efficiency.

The GL roller chain coupling transmits movement and power in a long distance.It can work under low speed, heavy load and high temperature conditions and dusty conditions.It can ensure the accurate transmission ratio, the transmission power is large, and the force acting on the shaft is small.High transmission efficiency.

The disadvantage is that after the hinge of the chain is worn out, the pitch becomes larger and the joint is disjointed.Installation and maintenance requirements are high.

The advantages of gear transmission are: It can ensure a constant instantaneous transmission ratio, high stability, and accurate and reliable transmission of movement.The range of transmitted power and speed is large.The structure is compact, the work is reliable, and the larger transmission ratio can be achieved.High transmission efficiency and long service life.The disadvantages are: high manufacturing and installation requirements.

The advantages of gear transmission are: It can ensure a constant instantaneous transmission ratio, high stability, and accurate and reliable transmission of movement.The range of transmitted power and speed is large.The structure is compact, the work is reliable, and the larger transmission ratio can be achieved.High transmission efficiency and long service life.The disadvantages are: high manufacturing and installation requirements.

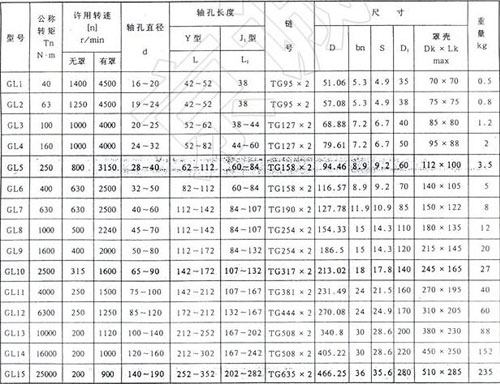

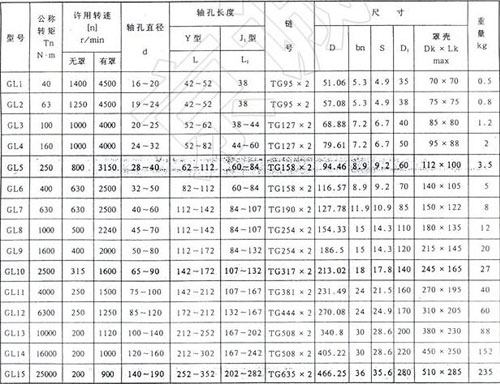

Parameters and dimensions of CL type coupling

Previous:KC roller chain coupling

Next:Nothing

Related Products: