Tooth Coupling for Pet Food Manufacturing

Introduction:

In the pet food manufacturing industry, tooth coupling plays a crucial role in ensuring the efficiency and reliability of the production process. This article aims to provide a comprehensive overview of tooth coupling and its significance in the pet food manufacturing industry.

1. Understanding Tooth Coupling

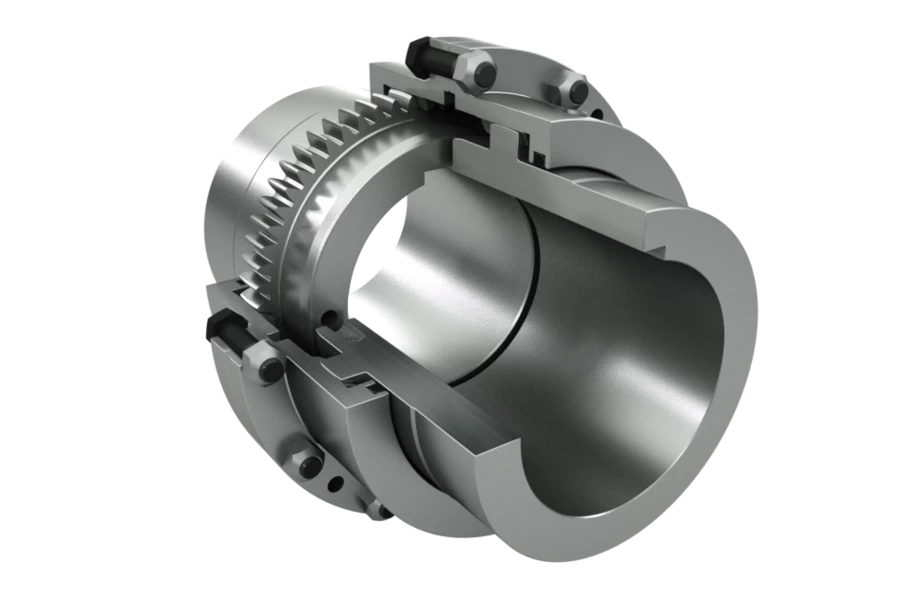

Tooth coupling, also known as gear coupling, is a mechanical device used to connect two shafts together while transmitting power and torque. It consists of two hubs with external teeth that interlock with a flexible sleeve, known as the coupling element or spider.

2. Advantages of Tooth Coupling in Pet Food Manufacturing

2.1 Enhanced Power Transmission Efficiency:

Tooth coupling offers high power transmission efficiency due to its precise tooth engagement, minimizing power losses during the pet food production process.

2.2 Shock and Vibration Damping:

With its flexible design, tooth coupling effectively absorbs shocks and vibrations generated during the manufacturing process, reducing wear and tear on the machinery.

2.3 Misalignment Compensation:

Tooth coupling can accommodate both angular and parallel misalignments between shafts, ensuring smooth operation and preventing premature failure of the equipment.

2.4 Compact and Space-Saving:

Due to its compact design, tooth coupling occupies less space, making it suitable for pet food manufacturing plants with limited floor space.

2.5 Increased Durability:

With its robust construction and high-quality materials, tooth coupling offers exceptional durability, reducing the frequency of maintenance and replacement.

3. Lubrication of Tooth Coupling

Lubrication is vital for the proper functioning and longevity of tooth coupling in pet food manufacturing. It helps reduce friction, wear, and heat generation, ensuring optimal performance. It is recommended to use high-quality lubricants specifically designed for tooth couplings and follow the manufacturer’s guidelines for lubrication intervals.

4. Choosing and Customizing the Right Tooth Coupling

When selecting or customizing a tooth coupling for pet food manufacturing, it is essential to consider the following parameters and real-world conditions:

4.1 Torque Requirements:

Calculate the maximum torque the coupling needs to transmit to ensure it can handle the specific demands of the pet food manufacturing process.

4.2 Shaft Size and Speed:

Determine the shaft diameter and rotational speed to select a tooth coupling that matches the requirements of the pet food manufacturing machinery.

4.3 Misalignment Compensation:

Evaluate the expected misalignment between the shafts and choose a tooth coupling that can effectively compensate for both angular and parallel misalignments.

4.4 Environmental Conditions:

Consider factors such as temperature, humidity, and exposure to chemicals or contaminants to select a tooth coupling with suitable corrosion resistance and environmental durability.

4.5 Maintenance and Serviceability:

Assess the ease of maintenance and availability of spare parts when choosing a tooth coupling to minimize production downtime and ensure long-term reliability.

Conclusion

HZPT, located in Hangzhou, Zhejiang province, is a modern enterprise specializing in the research, development, production, and international trade of quality couplings. Our company offers a wide range of tooth couplings for pet food manufacturing, catering to the unique requirements of the industry.

Our Advantages:

1. High Power Transmission Efficiency: Our tooth couplings ensure efficient power transmission, maximizing the productivity of pet food manufacturing processes.

2. Exceptional Shock and Vibration Damping: Designed to absorb shocks and vibrations, our tooth couplings minimize machinery wear and extend equipment lifespan.

3. Accurate Misalignment Compensation: Our tooth couplings can handle angular and parallel misalignments, ensuring smooth operation and reducing downtime.

4. Space-Saving Design: With their compact size, our tooth couplings optimize space utilization, allowing for efficient layout planning in pet food manufacturing plants.

5. Reliable and Durable: Our tooth couplings are constructed with high-quality materials, providing long-lasting performance and minimizing maintenance requirements.