Hello, welcome to Cangzhou Ever-Power Co., Ltd.!

- Tyre coupling

- Flexible log-off coupling

- Flange coupling

- Universal coupling

- Roller sprocket coupling

- Drum type gear coupling

- Star elastic coupling

- Plum elastic coupling

- Oldham coupling

- Clamping coupling

- With brake disc coupling

- Snake-shaped yellow coupling

- Diaphragm coupling

- Nylon internal gear coupling

Contact Us

your present location:HOME > Diaphragm coupling > Nylon internal gear coupling >

Nylon internal gear coupling

Nylon internal gear coupling

Time: 2019-05-21 20:37 Author: admin Click:

Nylon rod coupling:

The entire tooth root of the nylon rod coupling is rounded and the pressure angle of the gear is 200. Its yield strength is higher than that of the 14.50 pressure angle gear. Its load capacity is 15% higher than the latter, or its use can be extended under the same conditions. Lifespan 3.5

Times.

1. Under the condition of meeting the load, consider selecting the design of the tooth, so that the tooth heat generated by high-speed operation is less;

2. In order to make the gears have higher torque, you can consider casting the machined steel parts directly in the gears;

3. Under the provided environmental factors such as temperature, humidity and chemical conditions, MC nylon gears are usually superior to other engineering plastics;

4. The choice of materials depends on both the environment and the operating conditions.

Characteristics and specifications of drum gear coupling:

The transmission efficiency of the drum gear coupling is as high as 99.7%.Based on the characteristics of the warp, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings. The drum-shaped gear coupling produced by UMA has a complete range of specifications and conforms to the corresponding standards.The drum-shaped gear coupling has high rigidity, flexibility, and no elasticity, so it is not suitable for machinery that requires damping, buffering, and two-axis alignment.

The entire tooth root of the nylon rod coupling is rounded and the pressure angle of the gear is 200. Its yield strength is higher than that of the 14.50 pressure angle gear. Its load capacity is 15% higher than the latter, or its use can be extended under the same conditions. Lifespan 3.5

Times.

1. Under the condition of meeting the load, consider selecting the design of the tooth, so that the tooth heat generated by high-speed operation is less;

2. In order to make the gears have higher torque, you can consider casting the machined steel parts directly in the gears;

3. Under the provided environmental factors such as temperature, humidity and chemical conditions, MC nylon gears are usually superior to other engineering plastics;

4. The choice of materials depends on both the environment and the operating conditions.

Characteristics and specifications of drum gear coupling:

The transmission efficiency of the drum gear coupling is as high as 99.7%.Based on the characteristics of the warp, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings. The drum-shaped gear coupling produced by UMA has a complete range of specifications and conforms to the corresponding standards.The drum-shaped gear coupling has high rigidity, flexibility, and no elasticity, so it is not suitable for machinery that requires damping, buffering, and two-axis alignment.

The drum-shaped gear coupling has strong load-bearing capacity.Under the same outer diameter of the inner gear sleeve and the outer diameter of the coupling, the carrying capacity of the drum gear coupling is 15-20% higher than that of the straight gear coupling on average;

The angular displacement compensation of the drum-shaped gear coupling is large.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1º; while the allowable angular displacement of the drum gear coupling is 1º; 30”, an increase of 50%, in the same mold Under the condition of number, number of teeth and tooth width, the allowable angular displacement of the drum gear is larger than that of the straight tooth.

The tooth end of the outer gear sleeve of the drum-shaped gear coupling is in the shape of a horn, which makes the assembly and disassembly of the inner and outer gears very convenient.The drum-shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration of the straight tooth under the condition of angular displacement, and at the same time improves the friction and wear of the tooth surface, and reduces the noise. Long maintenance period.

The role of the coupling:

The coupling is installed between the driving side and the passive side of the power transmission to transmit rotating torque, compensate for the installation deviation between shafts, absorb equipment vibration and buffer load impact.One of the functions of the coupling is to absorb and compensate the deviation between the shaft and the shaft through its own deformation.The greater the flexibility, the stronger the ability to absorb deviations; the smaller the flexibility, the weaker the ability to absorb deviations.Generally speaking, this kind of shaft-to-axis deviation is divided into the following three aspects: The connection between the coupling and the peripheral equipment is realized by inserting the shaft of the equipment into the shaft hole of the coupling.The shaft hole of the coupling generally has a keyway type, a clamping type, a clamping + keyway, a screw type, an expansion type and so on.The keyway type is widely used, suitable for ordinary motors, ordinary reducers and ordinary drive shafts.The clamping type is more widely used in servo motors, stepping motors, and various types of synchronous transmission shafts. The shaft and the hole are closely matched without any transmission gap. If the keyway structure is added, the torque transmission capacity can be enhanced.The top wire type is suitable for small shaft diameter and small torque transmission occasions, such as micro motors, encoders, etc.

The characteristics of the coupling:

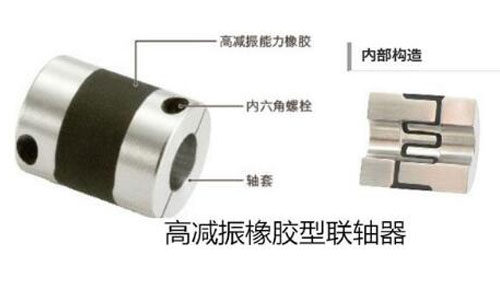

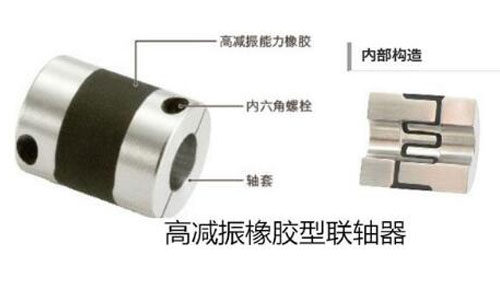

1. High shock absorption rubber type

Applicable occasions: It can mainly realize the high gain of the servo motor and shorten the setting time.It also helps to suppress the speed deviation when the stepping motor is driven.

Disadvantages: expensive and not resistant to high temperatures.

2. Diaphragm type

The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the connected two shafts. It is a high-performance flexible coupling with strong metal components.

Applicable occasions: respond to high speed conditions.

Advantages: no lubrication, compact structure, high strength, long service life, no rotation gap, not affected by temperature and oil pollution, acid, alkali and corrosion resistance, eccentricity, deflection angle and axial deviation can be allowed, suitable It is suitable for shafting transmission in high temperature, high speed, and corrosive environment.

Disadvantages: The eccentric deflection angle that can be absorbed is relatively small, the shape is complicated, the processing is time-consuming, and it is inconvenient to use for heavy lifting cranes.

3. Slit type

Slotted on the bar, a fully integrated metal flexible coupling.

Applicable occasions: suitable for high-speed and high-precision positioning of servo motors, etc.

Advantages: high accuracy, extremely high torsional rigidity, low moment of inertia, eccentricity, deflection angle, and axial deviation are also allowed.

Disadvantages: easy to break

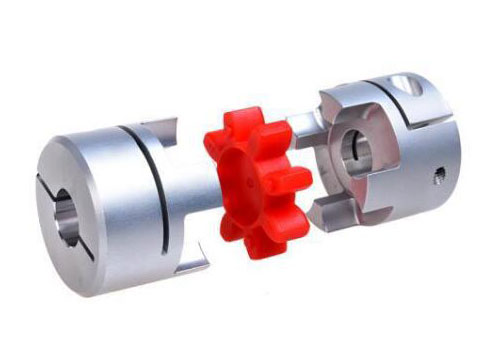

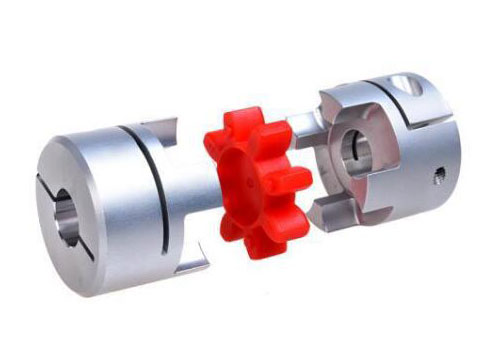

4. Plum blossom type

Applicable occasions: suitable for working occasions with frequent starting, forward and reverse rotation, medium and high speed, medium torque and high reliability.

Advantages: simple structure, convenient maintenance, maintenance-free, continuous long-term operation.Large carrying capacity, with good vibration damping, buffering and electrical insulation properties.It has large axial, radial and angular compensation capabilities.The radial size is small, the weight is light, and the moment of inertia is small, which is suitable for medium and high speed applications.

Disadvantages: Teeth breaking easily occurs at high speeds or high loads, and it is not resistant to high temperatures.

5. Bellows type

Applicable occasions: high sensitivity and rapid response, making it ideal for extremely small and precise instrument applications

Advantages: no gap, high sensitivity; high elasticity, better protection of equipment; can absorb vibration, while compensating for radial, angular and axial deviation; strong resistance to oil stains, corrosion resistance; torsional rigidity, smooth The clockwise and counterclockwise rotation characteristics are exactly the same.

Disadvantages: small torque, high price, long delivery time.

6. Cross slider type

Applicable occasions: generally used in places where the speed is n<250r/min, the rigidity of the shaft is relatively large, and there is no severe impact.

Advantages: allow a large eccentric angle, good error adjustment effect, reduce the burden on the shaft, simple structure, convenient assembly, and electrical insulation;

Disadvantages: poor impact resistance; easy to wear between the slider and the groove and need to be lubricated; due to radial displacement, a large centrifugal inertia force is generated, which brings additional load to the shaft and bearing.

The angular displacement compensation of the drum-shaped gear coupling is large.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1º; while the allowable angular displacement of the drum gear coupling is 1º; 30”, an increase of 50%, in the same mold Under the condition of number, number of teeth and tooth width, the allowable angular displacement of the drum gear is larger than that of the straight tooth.

The tooth end of the outer gear sleeve of the drum-shaped gear coupling is in the shape of a horn, which makes the assembly and disassembly of the inner and outer gears very convenient.The drum-shaped tooth surface improves the contact conditions of the inner and outer teeth, avoids the disadvantages of edge extrusion and stress concentration of the straight tooth under the condition of angular displacement, and at the same time improves the friction and wear of the tooth surface, and reduces the noise. Long maintenance period.

The role of the coupling:

The coupling is installed between the driving side and the passive side of the power transmission to transmit rotating torque, compensate for the installation deviation between shafts, absorb equipment vibration and buffer load impact.One of the functions of the coupling is to absorb and compensate the deviation between the shaft and the shaft through its own deformation.The greater the flexibility, the stronger the ability to absorb deviations; the smaller the flexibility, the weaker the ability to absorb deviations.Generally speaking, this kind of shaft-to-axis deviation is divided into the following three aspects: The connection between the coupling and the peripheral equipment is realized by inserting the shaft of the equipment into the shaft hole of the coupling.The shaft hole of the coupling generally has a keyway type, a clamping type, a clamping + keyway, a screw type, an expansion type and so on.The keyway type is widely used, suitable for ordinary motors, ordinary reducers and ordinary drive shafts.The clamping type is more widely used in servo motors, stepping motors, and various types of synchronous transmission shafts. The shaft and the hole are closely matched without any transmission gap. If the keyway structure is added, the torque transmission capacity can be enhanced.The top wire type is suitable for small shaft diameter and small torque transmission occasions, such as micro motors, encoders, etc.

The characteristics of the coupling:

1. High shock absorption rubber type

Applicable occasions: It can mainly realize the high gain of the servo motor and shorten the setting time.It also helps to suppress the speed deviation when the stepping motor is driven.

Disadvantages: expensive and not resistant to high temperatures.

2. Diaphragm type

The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the connected two shafts. It is a high-performance flexible coupling with strong metal components.

Applicable occasions: respond to high speed conditions.

Advantages: no lubrication, compact structure, high strength, long service life, no rotation gap, not affected by temperature and oil pollution, acid, alkali and corrosion resistance, eccentricity, deflection angle and axial deviation can be allowed, suitable It is suitable for shafting transmission in high temperature, high speed, and corrosive environment.

Disadvantages: The eccentric deflection angle that can be absorbed is relatively small, the shape is complicated, the processing is time-consuming, and it is inconvenient to use for heavy lifting cranes.

3. Slit type

Slotted on the bar, a fully integrated metal flexible coupling.

Applicable occasions: suitable for high-speed and high-precision positioning of servo motors, etc.

Advantages: high accuracy, extremely high torsional rigidity, low moment of inertia, eccentricity, deflection angle, and axial deviation are also allowed.

Disadvantages: easy to break

4. Plum blossom type

Applicable occasions: suitable for working occasions with frequent starting, forward and reverse rotation, medium and high speed, medium torque and high reliability.

Advantages: simple structure, convenient maintenance, maintenance-free, continuous long-term operation.Large carrying capacity, with good vibration damping, buffering and electrical insulation properties.It has large axial, radial and angular compensation capabilities.The radial size is small, the weight is light, and the moment of inertia is small, which is suitable for medium and high speed applications.

Disadvantages: Teeth breaking easily occurs at high speeds or high loads, and it is not resistant to high temperatures.

5. Bellows type

Applicable occasions: high sensitivity and rapid response, making it ideal for extremely small and precise instrument applications

Advantages: no gap, high sensitivity; high elasticity, better protection of equipment; can absorb vibration, while compensating for radial, angular and axial deviation; strong resistance to oil stains, corrosion resistance; torsional rigidity, smooth The clockwise and counterclockwise rotation characteristics are exactly the same.

Disadvantages: small torque, high price, long delivery time.

6. Cross slider type

Applicable occasions: generally used in places where the speed is n<250r/min, the rigidity of the shaft is relatively large, and there is no severe impact.

Advantages: allow a large eccentric angle, good error adjustment effect, reduce the burden on the shaft, simple structure, convenient assembly, and electrical insulation;

Disadvantages: poor impact resistance; easy to wear between the slider and the groove and need to be lubricated; due to radial displacement, a large centrifugal inertia force is generated, which brings additional load to the shaft and bearing.

Previous:NL type nylon internal gear coupling

Next:Nothing

Related Products: