Product Description

High Quality Steel Tooth Flexible Rubber Plastic Falk Flexible Nylon Sleeve Universal Joints Chainbox Muff Gear Coupling Replacement of Bowex Coupling

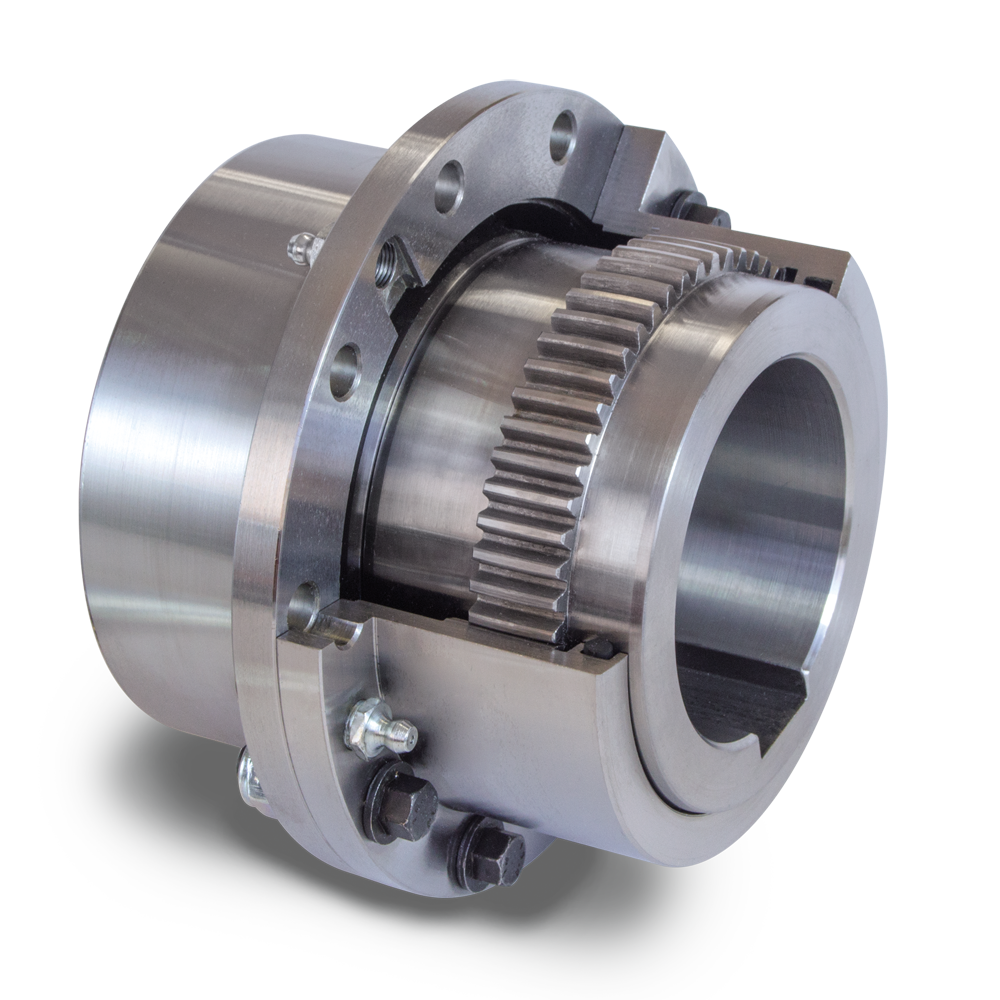

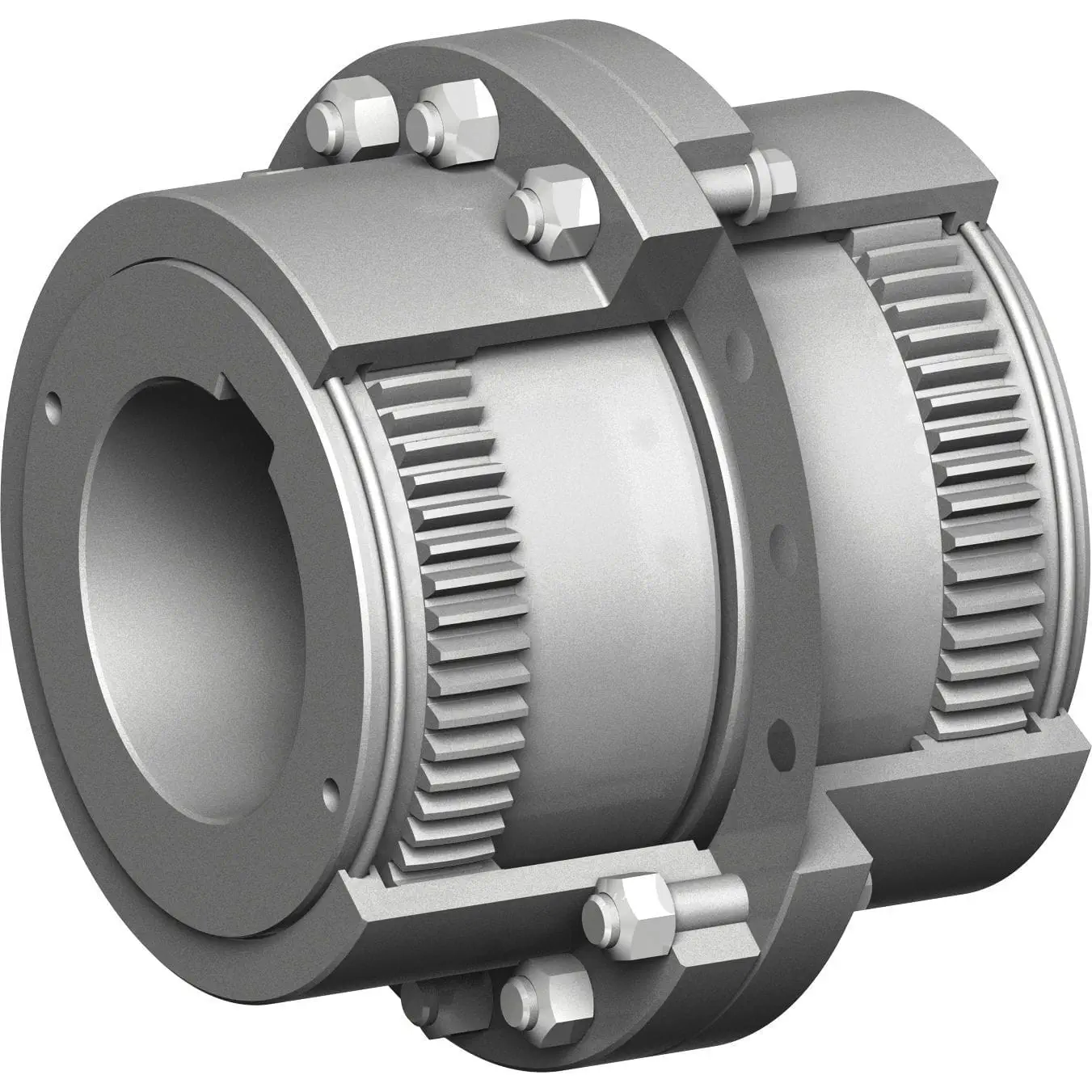

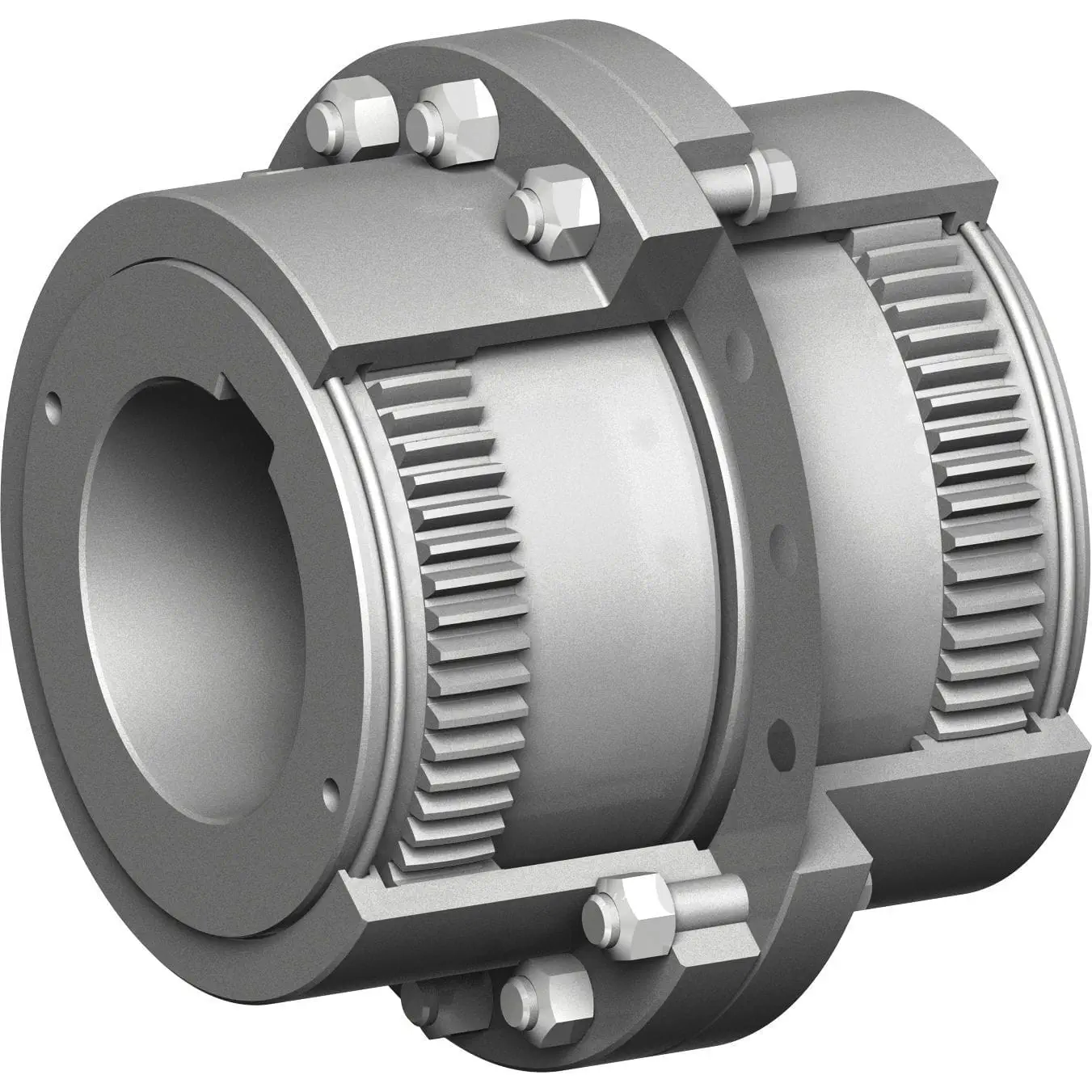

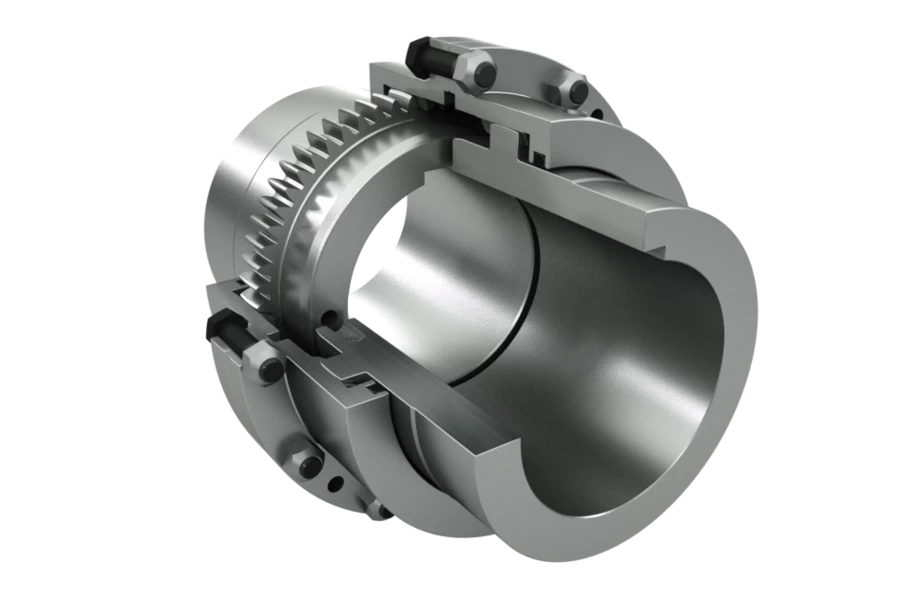

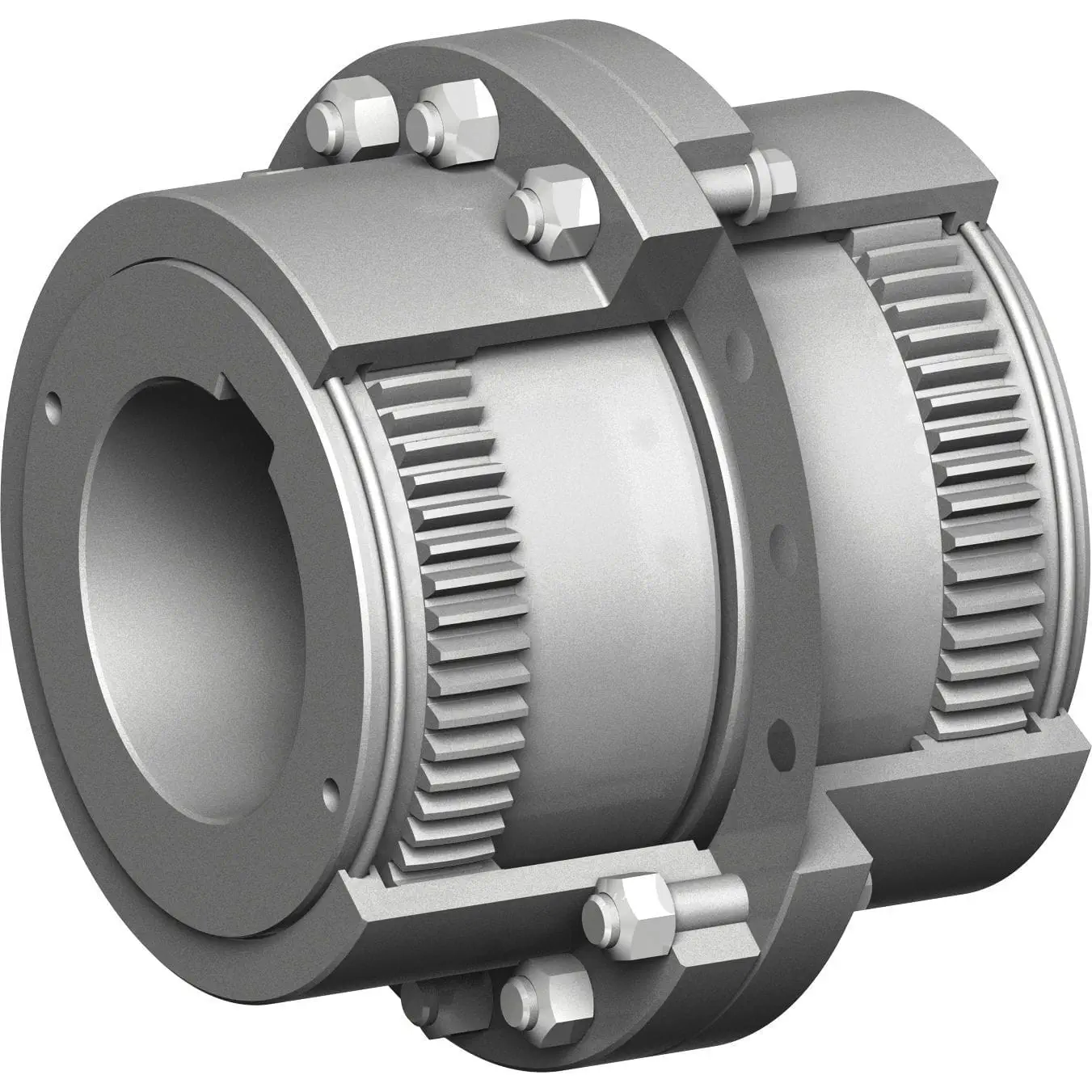

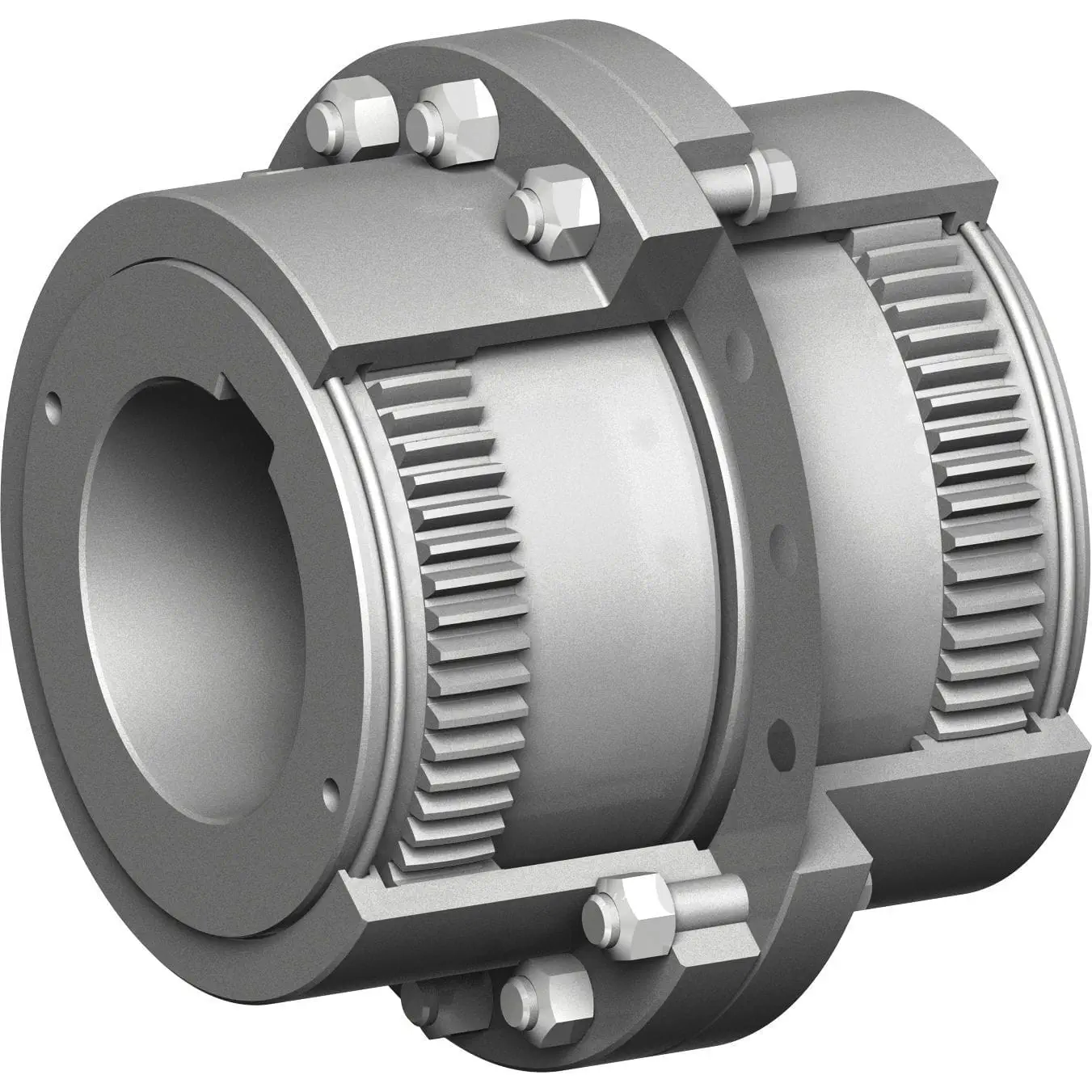

A gear coupling is a type of mechanical coupling that is used to connect 2 shafts at their ends to transmit torque and rotational motion. It consists of 2 hubs with external teeth connected by a flexible element, typically a sleeve or a disk, with internal teeth.

The hubs are usually made of steel or other high-strength materials, and the teeth are cut using precision machining techniques to ensure proper fit and alignment. The flexible element is designed to compensate for any misalignment between the 2 shafts and to allow for a slight amount of angular and axial misalignment during operation.

Gear couplings are commonly used in heavy-duty applications, such as in large machinery and industrial equipment, where high torque and precision are required. They are also used in applications where shafts are subjected to significant amounts of vibration and shock, such as in marine and aerospace applications.

One of the advantages of gear couplings is that they are highly efficient at transmitting torque, with very little energy loss. They are also durable and require minimal maintenance, making them popular in many industries.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Tooth Couplings with Gear and Jaw Couplings

Tooth couplings, gear couplings, and jaw couplings are all types of couplings used in mechanical systems. Here’s a comparison of tooth couplings with gear and jaw couplings:

Tooth Couplings:

- They have interlocking teeth that provide high torque transmission capacity.

- Offer excellent misalignment compensation due to the tooth design.

- Can handle angular, radial, and axial misalignment.

- Transmit torque with low backlash and high torsional stiffness.

Gear Couplings:

- Use gears to transmit torque, providing high torque capacity.

- Handle angular misalignment but are less effective with radial and axial misalignment.

- Have backlash due to the gear design, which can affect precision applications.

- Require periodic lubrication and maintenance.

Jaw Couplings:

- Use elastomeric elements (jaws) for torque transmission.

- Provide good torsional stiffness and misalignment compensation.

- Handle moderate angular and axial misalignment but limited radial misalignment.

- Are simple in design and easy to install.

Ultimately, the choice between these couplings depends on the specific requirements of the application. Tooth couplings are preferred for high torque, precision, and demanding applications that require precise torque transmission and efficient misalignment compensation. Gear couplings excel in high torque situations but may have more backlash. Jaw couplings are suitable for simpler applications with moderate misalignment and torque requirements.

Influence of Teeth Profiles and Spacing on Tooth Coupling Performance

The design of teeth profiles and spacing in tooth couplings significantly impacts their performance in various ways:

1. Torque Transmission: The shape of teeth profiles determines how efficiently torque is transmitted between the two shafts. Properly designed profiles maximize the surface contact area, enhancing torque transmission capabilities.

2. Load Distribution: The teeth profiles and spacing affect how loads are distributed across the coupling. Even distribution helps prevent localized stress concentrations and ensures uniform wear and longevity.

3. Misalignment Compensation: Tooth couplings with specific teeth profiles and spacing can better accommodate angular, radial, and axial misalignments between shafts. This reduces the risk of excessive wear and prolongs coupling life.

4. Backlash and Precision: The teeth spacing impacts the level of backlash, or play, between the teeth during rotation. Smaller teeth spacing reduces backlash, leading to more precise and accurate motion transmission.

5. Noise and Vibration: Well-designed teeth profiles and spacing can minimize noise and vibration during operation by promoting smoother engagement and disengagement of teeth.

6. Fatigue Resistance: Proper teeth profiles and spacing help distribute stresses evenly, enhancing the coupling’s fatigue resistance against cyclic loads.

7. Material Selection: Teeth profiles and spacing also influence the choice of materials for the coupling. Certain profiles may require specific materials to ensure durability and optimal performance.

8. Efficiency: Optimized teeth profiles and spacing reduce friction and wear, resulting in higher coupling efficiency and less energy loss.

9. Customization: The flexibility to customize teeth profiles and spacing allows engineers to tailor the coupling’s performance to the specific application requirements.

Overall, the design of teeth profiles and spacing is a critical factor in determining the overall efficiency, durability, precision, and performance of tooth couplings in various mechanical systems.

Role of Tooth Couplings in Mechanical Systems

A tooth coupling is a type of mechanical coupling that connects two shafts to transmit torque while allowing for angular misalignment and axial movement between them. It consists of two hubs with external teeth that mesh together, engaging the teeth to transfer torque from one shaft to another. Tooth couplings are commonly used in various mechanical systems to provide a reliable and efficient means of transmitting power and motion.

editor by CX 2024-01-10

China Best Sales Sg7-Zl/Zld Type China Factory Pin Tooth Flexible Gear Coupling

Product Description

SG7-ZL/ZLD Type China Factory Pin Tooth Flexible Gear Coupling

Product Description

Features

1.Huge torsion of transmission,small size,light weight

2.No need librations,easy to maintain

Material:Carbon Steel

Application:Suitable for medium and large power shaft transmission

Remark

1.The coupling approximation is the driving moment of inertia and weight

2.Bore dimensions can be customized

Drawing of SG7-ZL/ZLD Type China Factory Pin Tooth Flexible Gear Coupling

Packaging & Shipping

| Packaging Detail: | Plastic Bag + Standard Color Box + Carton |

| Delivery Detail: | 15-30 days(It is up to your order) |

| Shipment: | DHL / Fedex / UPS etc. |

Our Services

| Design ideas | ||||||||||

| Shang Kun industrial hardware is a professional factory for hinge and latch, the quality of our product is very good and the price is reasonable, the entire products design aesthetic generous, With our own R&D team and strong ability of material sourcing, we are always competent for most of requirement from customers. We have established a strict quality control system in factory, so,it is the perfect goods for your choice. | ||||||||||

| Quality Control | ||||||||||

| All the material is provided by specialized supplies. so we do not cut corners, the weight is natural, and the hinge’s working life is very long, so it has a good value. We can provide many kinds of different material quality series products for your chose. | ||||||||||

| Service | ||||||||||

| *Customized logo: Acceptable | ||||||||||

| *Changing on material, mould, shape: Acceptable | ||||||||||

| *Develop on Artwork and Sketch: Acceptable | ||||||||||

| *Packing: Acceptable | ||||||||||

| *Sample: Acceptable | ||||||||||

| MOQ | ||||||||||

| Kindly, as to the smallest volume of order, we welcome buyers different size at least, at this stage and thus currently we have no strict limit on MOQ. | ||||||||||

| Payment | ||||||||||

| We accept many types of payment terms, such as TT, Paypal, Western Union, etc. Just according to your requirment. |

Company Information

FAQ

FAQ

1.Manufacturer supply:Direct production.There are inventory,fast delivery,quality assured!

2.About the size:all kinds of specification complete varieties.

3.About the color:according to your requirements.

4.About the services:24 hours,provide you with the latest prodect information and services.

5.About the after sale services:24 hours online provide service for you.

6.About the shipments:we have in stock,will delivery for you as soon as possible.

Related Products

Contact

Feel free to contact us!

| HangZhou Shangkun Industrial Technology Co.,LTD |

| Address: No.39, Shi Chang Road ,Zhuan Yao Industrial Area, Xihu (West Lake) Dis.Cheng District, Xihu (West Lake) Dis.Guan, ZheJiang , China |

| Attn: Alaia |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Tooth Couplings in Various Industries

Tooth couplings find widespread use in a variety of industries and applications that require efficient torque transmission and the ability to accommodate misalignment. Some common examples include:

- Industrial Machinery: Tooth couplings are frequently used in industrial machinery such as conveyors, mixers, pumps, and compressors. These applications often involve heavy loads and varying operating conditions where reliable torque transmission is essential.

- Automotive: In automotive applications, tooth couplings can be found in drivetrain systems, power transmission, and other components that require efficient torque transfer between rotating shafts.

- Marine: Tooth couplings are utilized in marine propulsion systems, where they help transmit torque from engines to propellers, ensuring smooth and reliable operation of vessels.

- Energy Generation: Power plants, including those for electricity generation and renewable energy sources, use tooth couplings in various equipment like turbines and generators to transfer rotational energy.

- Material Handling: Tooth couplings play a role in material handling equipment such as cranes, hoists, and elevators, where they assist in moving and lifting heavy loads.

- Mining and Construction: Industries like mining and construction rely on tooth couplings for equipment such as excavators, loaders, and crushers, which require robust torque transmission capabilities.

These examples illustrate the versatility of tooth couplings across different sectors where dependable torque transmission and misalignment compensation are vital for operational efficiency and reliability.

Specialized Maintenance Practices for Longevity of Tooth Couplings

To ensure the longevity of tooth couplings, specialized maintenance practices should be followed:

- Lubrication: Proper lubrication is crucial to reduce friction and wear between the teeth. Use lubricants recommended by the coupling manufacturer and ensure regular lubrication.

- Lubricant Quality: Use high-quality lubricants with suitable viscosity and additives for optimal performance and protection against corrosion.

- Lubrication Frequency: Follow the manufacturer’s recommendations for lubrication intervals. Factors such as operating conditions and environment can influence the frequency.

- Alignment: Maintain proper alignment of connected shafts to prevent excessive load and wear on the teeth. Misalignment can lead to premature failure.

- Inspection: Regularly inspect tooth couplings for signs of wear, damage, or misalignment. Early detection allows for timely repairs or replacements.

- Torque Monitoring: Monitor transmitted torque to ensure it remains within the coupling’s rated capacity. Excessive torque can lead to overloading and damage.

- Temperature: Monitor coupling temperature during operation. Elevated temperatures could indicate problems like inadequate lubrication or misalignment.

- Vibration Analysis: Use vibration analysis tools to detect abnormal vibrations that may indicate coupling issues or misalignment.

- Professional Inspection: Periodically have a professional inspect and assess the condition of the tooth coupling. They can identify potential issues that might go unnoticed.

- Replace Worn Parts: If wear or damage is detected, replace worn components promptly to prevent further deterioration.

- Manufacturer Guidelines: Adhere to the manufacturer’s maintenance recommendations and guidelines for the specific tooth coupling model.

Following these specialized maintenance practices can help ensure the reliable operation and extended lifespan of tooth couplings in machinery systems.

Proper Installation and Maintenance of Tooth Couplings

To ensure the proper function and longevity of a tooth coupling, follow these guidelines:

Installation:

- Ensure shafts are aligned within manufacturer specifications to prevent excessive loads on the coupling.

- Clean and inspect the coupling components before installation to avoid debris or contaminants.

- Use appropriate tools and methods to achieve proper fit between the coupling and the shafts.

- Follow the manufacturer’s instructions for tightening bolts or fasteners to the recommended torque.

Maintenance:

- Regularly inspect the coupling for signs of wear, such as tooth damage, corrosion, or misalignment.

- Check for any abnormal vibrations, noise, or overheating during operation, which could indicate coupling issues.

- Keep the coupling and surrounding area clean to prevent the accumulation of dirt or debris.

- Regularly lubricate the coupling as per the manufacturer’s recommendations to reduce friction and wear.

- Monitor the alignment of the connected equipment and address any misalignment promptly.

- Replace worn or damaged components promptly to avoid further damage and maintain coupling performance.

Following proper installation and maintenance practices will help maximize the efficiency and service life of the tooth coupling.

editor by CX 2023-12-25

China Good quality Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CHINAMFG Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Applications of Tooth Couplings in Various Industries

Tooth couplings find widespread use in a variety of industries and applications that require efficient torque transmission and the ability to accommodate misalignment. Some common examples include:

- Industrial Machinery: Tooth couplings are frequently used in industrial machinery such as conveyors, mixers, pumps, and compressors. These applications often involve heavy loads and varying operating conditions where reliable torque transmission is essential.

- Automotive: In automotive applications, tooth couplings can be found in drivetrain systems, power transmission, and other components that require efficient torque transfer between rotating shafts.

- Marine: Tooth couplings are utilized in marine propulsion systems, where they help transmit torque from engines to propellers, ensuring smooth and reliable operation of vessels.

- Energy Generation: Power plants, including those for electricity generation and renewable energy sources, use tooth couplings in various equipment like turbines and generators to transfer rotational energy.

- Material Handling: Tooth couplings play a role in material handling equipment such as cranes, hoists, and elevators, where they assist in moving and lifting heavy loads.

- Mining and Construction: Industries like mining and construction rely on tooth couplings for equipment such as excavators, loaders, and crushers, which require robust torque transmission capabilities.

These examples illustrate the versatility of tooth couplings across different sectors where dependable torque transmission and misalignment compensation are vital for operational efficiency and reliability.

Suitability of Tooth Couplings for High-Speed Rotation and Heavy Loads

Yes, tooth couplings are well-suited for applications that involve high-speed rotation and heavy loads. Here’s why:

High-Speed Rotation: Tooth couplings are designed to transmit torque efficiently even at high rotational speeds. The tooth engagement provides a reliable means of torque transmission without slippage, making them ideal for high-speed applications.

Heavy Loads: Tooth couplings are robust and capable of handling substantial loads due to the interlocking teeth design. The teeth provide a secure connection that can transmit high levels of torque without deformation or damage.

Accuracy and Precision: Tooth couplings offer precise and accurate torque transmission, making them suitable for applications where precise positioning or synchronization is essential.

Minimal Backlash: Tooth couplings generally have minimal backlash due to the tight meshing of teeth. This reduces the play between the connected shafts, ensuring consistent motion and accurate positioning.

Sturdiness: Tooth couplings are manufactured from durable materials, making them capable of withstanding the stresses and forces associated with heavy loads and high speeds.

Customization: Tooth couplings can be tailored to specific applications by adjusting parameters such as tooth profile, size, and materials. This allows engineers to optimize the coupling’s performance for the intended use.

Advanced Designs: Modern tooth coupling designs incorporate advanced engineering techniques, such as finite element analysis, to ensure optimal performance even under challenging conditions.

Overall, tooth couplings offer a reliable solution for applications that demand both high-speed rotation and the ability to handle heavy loads effectively.

Tooth Couplings: Torque Transmission and Misalignment Handling

Tooth couplings are designed to efficiently transmit torque while accommodating certain levels of misalignment between connected shafts. Here’s how they handle torque transmission and misalignment:

Torque Transmission: Tooth couplings utilize interlocking teeth on the coupling hubs to transfer torque from one shaft to another. The teeth engagement creates a strong mechanical connection that can transmit high levels of torque. The coupling’s design ensures even distribution of torque across the teeth, minimizing stress concentrations and enhancing the coupling’s overall strength.

Misalignment Handling: Tooth couplings can accommodate a limited amount of angular and axial misalignment between shafts. The interlocking teeth provide some flexibility, allowing the coupling to compensate for small angular deviations. Additionally, the teeth engagement can provide a degree of axial flexibility, enabling the coupling to handle slight axial misalignments. However, tooth couplings have lower misalignment tolerance compared to some other flexible coupling types like elastomeric couplings.

It’s important to note that excessive misalignment can lead to premature wear and reduced coupling life. Therefore, while tooth couplings offer misalignment compensation to a certain extent, proper alignment of the connected shafts is still essential to ensure optimal coupling performance and longevity.

editor by CX 2023-12-13

China Good quality Curved Teeth Drum Spline Motor Pump Flexible Marine Drive Shaft Gear Coupling

Product Description

Curved Teeth Drum Spline Motor Pump Flexible Marine Drive Shaft Gear Coupling

Product show

| Product Name | Densen customized GIICL gear motor shaft coupling,machine shaft coupling,flexible gear coupling |

| DN mm | 16-1040mm |

| Rated Torque | 0.4~4500 kN·m |

| Allowalbe Speed | 4000~460RPM |

| Material | 45# Steel or 42CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Why Choose Us

1. One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3. Your R&Dconsultant:

With professional engineers team and 29 years manufacture experience ,we would help you work out problems during new parts’ development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

No matter how long time the products delivered, we are responsible for the quality. In case the products be rejected, we would replace them or return fund according to your demand without hesitation

FAQQ1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

Misaligned Tooth Couplings: Challenges and Mitigation

Misalignment in tooth couplings can lead to various challenges that affect coupling performance and equipment reliability. Here are some challenges that can arise from misaligned tooth couplings and how they can be mitigated:

1. Increased Wear: Misalignment causes uneven loading and increased stress on the teeth of the coupling, leading to accelerated wear and potential tooth damage.

2. Reduced Efficiency: Misaligned couplings can result in energy losses due to increased friction and inefficient torque transmission.

3. Vibration and Noise: Misalignment can induce vibration and noise in the machinery system, affecting both operator comfort and equipment lifespan.

4. Premature Failure: Excessive misalignment can lead to premature coupling failure and unexpected downtime.

To mitigate these challenges, consider the following steps:

1. Proper Alignment: Ensure that the connected shafts are aligned within the specified tolerances. Use alignment tools and techniques to achieve accurate shaft alignment.

2. Regular Inspection: Perform routine inspections of the coupling to detect any signs of wear, damage, or misalignment. Address any issues promptly.

3. Lubrication: Proper lubrication reduces friction and wear, especially in misaligned conditions. Follow manufacturer guidelines for lubrication frequency and type.

4. Coupling Maintenance: Follow recommended maintenance practices provided by the coupling manufacturer to extend its lifespan and performance.

By addressing misalignment issues proactively and following proper maintenance practices, you can ensure the optimal performance and longevity of tooth couplings in your machinery systems.

Backlash in Tooth Couplings and Its Impact on Performance

Backlash is a crucial factor in tooth couplings that affects their performance. Backlash refers to the angular movement or play between the teeth of the coupling when there is a change in the direction of loading. It is the amount by which a tooth space exceeds the thickness of the engaged tooth.

The impact of backlash on performance includes:

- Positioning Accuracy: Backlash can lead to positioning inaccuracies in systems where precise motion control is required. As the direction of loading changes, the teeth need to engage before transmitting torque, causing a delay and affecting accuracy.

- Reversal Shock: In systems with frequent changes in direction, backlash can result in a sudden impact or shock when the teeth engage, leading to vibrations and potential damage to the coupling and connected components.

- System Response: Backlash can introduce a dead zone or delay in the system response when the loading direction changes. This can affect the system’s ability to respond quickly to changes in input.

- Reduced Efficiency: Backlash causes energy loss due to the need to overcome the play between teeth during direction changes. This can reduce the overall efficiency of the system.

- Wear and Fatigue: Backlash can lead to wear and fatigue of the coupling teeth and other components due to repeated impacts during loading changes.

- Noise and Vibration: The sudden engagement of teeth can generate noise and vibration, affecting the overall smoothness of operation and potentially leading to fatigue failure.

Minimizing backlash is important for improving the performance of tooth couplings. Some couplings are designed with features to reduce or compensate for backlash, while others require precise alignment and regular maintenance to manage backlash within acceptable limits.

Factors for Selecting a Tooth Coupling

When choosing a tooth coupling for a specific application, consider the following factors:

- Load and Torque: Determine the maximum load and torque requirements of the application to ensure the coupling can handle the expected forces.

- Speed: Consider the rotational speed of the equipment as higher speeds may require specialized couplings with enhanced balance and accuracy.

- Alignment Tolerance: Evaluate the degree of misalignment the coupling can accommodate without affecting performance.

- Environment: Assess the operating environment, including temperature, humidity, and exposure to contaminants or corrosive substances.

- Size and Space: Choose a coupling size that fits within the available space and meets the connection requirements of the shafts.

- Backlash: Determine the acceptable level of backlash, as some applications may require minimal or zero backlash for precise motion.

- Shock and Vibration: Consider whether the application involves frequent shocks or vibrations and choose a coupling that can dampen these effects.

- Material: Select the appropriate coupling material based on factors like corrosion resistance, strength, and compatibility with the connected components.

- Maintenance: Evaluate the ease of maintenance, including access to lubrication points and the need for periodic inspection and replacement.

- Cost: Balance the performance requirements with the budget constraints of the project.

Considering these factors will help you choose the right tooth coupling for your specific application, ensuring optimal performance and reliability.

editor by CX 2023-12-07

China supplier High Quality Steel Tooth Flexible Rubber Plastic Falk Flexible Nylon Sleeve Universal Joints Chainbox Muff Gear Coupling Replacement of Bowex Coupling

Product Description

High Quality Steel Tooth Flexible Rubber Plastic Falk Flexible Nylon Sleeve Universal Joints Chainbox Muff Gear Coupling Replacement of Bowex Coupling

A gear coupling is a type of mechanical coupling that is used to connect 2 shafts at their ends to transmit torque and rotational motion. It consists of 2 hubs with external teeth connected by a flexible element, typically a sleeve or a disk, with internal teeth.

The hubs are usually made of steel or other high-strength materials, and the teeth are cut using precision machining techniques to ensure proper fit and alignment. The flexible element is designed to compensate for any misalignment between the 2 shafts and to allow for a slight amount of angular and axial misalignment during operation.

Gear couplings are commonly used in heavy-duty applications, such as in large machinery and industrial equipment, where high torque and precision are required. They are also used in applications where shafts are subjected to significant amounts of vibration and shock, such as in marine and aerospace applications.

One of the advantages of gear couplings is that they are highly efficient at transmitting torque, with very little energy loss. They are also durable and require minimal maintenance, making them popular in many industries.

Industry Standards and Guidelines for Tooth Couplings

There are industry standards and guidelines that govern the design and use of tooth couplings. Some of these include:

- AGMA 9002-A94: This standard provides information on the selection and application of flexible couplings, including tooth couplings.

- ISO 14691: This international standard specifies methods for calculating the load capacity of tooth couplings.

- DIN 740: This German standard provides information on dimensions and requirements for tooth couplings.

- API 671: This American Petroleum Institute (API) standard specifies requirements for special purpose couplings, including tooth couplings, for use in the petroleum and natural gas industries.

These standards provide guidelines for the design, selection, installation, and maintenance of tooth couplings to ensure safe and reliable operation. Engineers and designers often refer to these standards to ensure that tooth couplings are used appropriately in various applications.

Specialized Maintenance Practices for Longevity of Tooth Couplings

To ensure the longevity of tooth couplings, specialized maintenance practices should be followed:

- Lubrication: Proper lubrication is crucial to reduce friction and wear between the teeth. Use lubricants recommended by the coupling manufacturer and ensure regular lubrication.

- Lubricant Quality: Use high-quality lubricants with suitable viscosity and additives for optimal performance and protection against corrosion.

- Lubrication Frequency: Follow the manufacturer’s recommendations for lubrication intervals. Factors such as operating conditions and environment can influence the frequency.

- Alignment: Maintain proper alignment of connected shafts to prevent excessive load and wear on the teeth. Misalignment can lead to premature failure.

- Inspection: Regularly inspect tooth couplings for signs of wear, damage, or misalignment. Early detection allows for timely repairs or replacements.

- Torque Monitoring: Monitor transmitted torque to ensure it remains within the coupling’s rated capacity. Excessive torque can lead to overloading and damage.

- Temperature: Monitor coupling temperature during operation. Elevated temperatures could indicate problems like inadequate lubrication or misalignment.

- Vibration Analysis: Use vibration analysis tools to detect abnormal vibrations that may indicate coupling issues or misalignment.

- Professional Inspection: Periodically have a professional inspect and assess the condition of the tooth coupling. They can identify potential issues that might go unnoticed.

- Replace Worn Parts: If wear or damage is detected, replace worn components promptly to prevent further deterioration.

- Manufacturer Guidelines: Adhere to the manufacturer’s maintenance recommendations and guidelines for the specific tooth coupling model.

Following these specialized maintenance practices can help ensure the reliable operation and extended lifespan of tooth couplings in machinery systems.

Role of Tooth Couplings in Mechanical Systems

A tooth coupling is a type of mechanical coupling that connects two shafts to transmit torque while allowing for angular misalignment and axial movement between them. It consists of two hubs with external teeth that mesh together, engaging the teeth to transfer torque from one shaft to another. Tooth couplings are commonly used in various mechanical systems to provide a reliable and efficient means of transmitting power and motion.

editor by CX 2023-11-16

China Best Sales CHINAMFG Custom Farm Gear Tooth Coupling, Flexible Gear Coupling

Product Description

Densen custom farm gear tooth coupling, gear shaft coupling, flexible gear coupling

Product show

| Product Name | Densen customized drum gear coupling,gear coupling,industrial gear c |

| DN mm | 16-1040mm |

| Rated Torque | 0.4~4500 kN·m |

| Allowalbe Speed | 4000~460RPM |

| Material | 45# Steel or 42CrMo |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Why Choose Us

1. One stop service:

We have 5 own factories and 50+ sub-contractors located in different areas of China to offer you one-stop manufacturing and purchasing services to help you save time and reduce procurement cost.

2. Your eyes in China:

Our commitment to quality permeates from quoting, scheduling, production, inspection to deliver into your warehouse, our QC team will remark the errors if has on QC documents for your checking before delivery as your 3rd party.

3. Your R&Dconsultant:

With professional engineers team and 29 years manufacture experience ,we would help you work out problems during new parts’ development, optimize design and recommend the most cost-effective solution.

4. Your Emergency Solver:

With continued grown factories team and our QC teams located in different areas, if customers need to expedite the delivery, we would be able to adopt another factory to produce together immediately.

5. Quality Guaranty:

No matter how long time the products delivered, we are responsible for the quality. In case the products be rejected, we would replace them or return fund according to your demand without hesitation

FAQQ1. Are you a manufacturer or a trader?

Manufacture, we have 5 own foundries, 4 in ZheJiang Province, 1 in ZHangZhoug Province

Q2. Do you have MOQ request?

1 pcs per order is ok with us , unless material is seldom used.

Q3. If I only have a sample,without drawings, can you quote then manufacture for me?

Just send us the sample, we would have the sample simulated and measured by professional equipment then issue formal drawings for

you , at the same time, we could help you optimize the design according to your demand and related processes’ feasibility.

Materials Used in Manufacturing Tooth Couplings

Common materials used in manufacturing tooth couplings include:

- Steel: Steel is a popular choice due to its high strength and durability. It can handle heavy loads and is suitable for a wide range of applications.

- Cast Iron: Cast iron is known for its excellent wear resistance and ability to dampen vibrations. It is often used in applications where shock absorption is important.

- Stainless Steel: Stainless steel is corrosion-resistant and can withstand harsh environments, making it suitable for industries like food processing and marine applications.

- Aluminum: Aluminum is lightweight and offers good corrosion resistance. It’s commonly used in applications where weight reduction is important.

- Bronze: Bronze is used for its self-lubricating properties and resistance to corrosion. It’s often employed in applications where lubrication is challenging.

The choice of material depends on factors such as the specific application, operating conditions, and required performance characteristics. Engineers select materials that offer the best combination of strength, durability, corrosion resistance, and other properties needed for the intended use of the tooth coupling.

Best Practices for Lubricating and Preserving Tooth Coupling Performance

Proper lubrication is essential for preserving the performance and extending the lifespan of tooth couplings. Here are the best practices for lubricating tooth couplings:

- Choose the Right Lubricant: Select a lubricant that is compatible with the material of the coupling and its operating conditions. Consult manufacturer recommendations for suitable lubricants.

- Regular Lubrication: Establish a regular lubrication schedule based on the coupling’s usage and operating conditions. Over-lubrication can cause issues, so follow recommended intervals.

- Clean Before Lubrication: Clean the coupling’s teeth and surfaces before applying lubricant to prevent debris and contaminants from mixing with the lubricant.

- Use Appropriate Amount: Apply the appropriate amount of lubricant to ensure proper coverage of the teeth and other moving parts. Excessive lubrication can attract dirt and lead to other problems.

- Distribute Lubricant Evenly: Ensure that the lubricant is evenly distributed across the teeth and mating surfaces for consistent lubrication during operation.

- Monitor Performance: Regularly monitor the coupling’s performance, noise levels, and any unusual vibrations. Changes in performance may indicate inadequate lubrication or other issues.

- Inspect and Reapply: During maintenance intervals, inspect the coupling for signs of wear or inadequate lubrication. Reapply lubricant as needed to maintain optimal performance.

- Temperature Considerations: Consider the operating temperature of the system when selecting a lubricant. Extreme temperatures can affect the viscosity and effectiveness of the lubricant.

- Environment: If the coupling operates in a harsh environment, choose a lubricant that offers protection against contaminants, moisture, and corrosion.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for lubrication frequency, lubricant type, and application methods.

Proper lubrication contributes to reducing friction, wear, and the risk of overheating, ensuring the tooth coupling operates smoothly and efficiently over its service life.

Factors for Selecting a Tooth Coupling

When choosing a tooth coupling for a specific application, consider the following factors:

- Load and Torque: Determine the maximum load and torque requirements of the application to ensure the coupling can handle the expected forces.

- Speed: Consider the rotational speed of the equipment as higher speeds may require specialized couplings with enhanced balance and accuracy.

- Alignment Tolerance: Evaluate the degree of misalignment the coupling can accommodate without affecting performance.

- Environment: Assess the operating environment, including temperature, humidity, and exposure to contaminants or corrosive substances.

- Size and Space: Choose a coupling size that fits within the available space and meets the connection requirements of the shafts.

- Backlash: Determine the acceptable level of backlash, as some applications may require minimal or zero backlash for precise motion.

- Shock and Vibration: Consider whether the application involves frequent shocks or vibrations and choose a coupling that can dampen these effects.

- Material: Select the appropriate coupling material based on factors like corrosion resistance, strength, and compatibility with the connected components.

- Maintenance: Evaluate the ease of maintenance, including access to lubrication points and the need for periodic inspection and replacement.

- Cost: Balance the performance requirements with the budget constraints of the project.

Considering these factors will help you choose the right tooth coupling for your specific application, ensuring optimal performance and reliability.

editor by CX 2023-10-23

China supplier Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

Product Description

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CHINAMFG Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

Misaligned Tooth Couplings: Challenges and Mitigation

Misalignment in tooth couplings can lead to various challenges that affect coupling performance and equipment reliability. Here are some challenges that can arise from misaligned tooth couplings and how they can be mitigated:

1. Increased Wear: Misalignment causes uneven loading and increased stress on the teeth of the coupling, leading to accelerated wear and potential tooth damage.

2. Reduced Efficiency: Misaligned couplings can result in energy losses due to increased friction and inefficient torque transmission.

3. Vibration and Noise: Misalignment can induce vibration and noise in the machinery system, affecting both operator comfort and equipment lifespan.

4. Premature Failure: Excessive misalignment can lead to premature coupling failure and unexpected downtime.

To mitigate these challenges, consider the following steps:

1. Proper Alignment: Ensure that the connected shafts are aligned within the specified tolerances. Use alignment tools and techniques to achieve accurate shaft alignment.

2. Regular Inspection: Perform routine inspections of the coupling to detect any signs of wear, damage, or misalignment. Address any issues promptly.

3. Lubrication: Proper lubrication reduces friction and wear, especially in misaligned conditions. Follow manufacturer guidelines for lubrication frequency and type.

4. Coupling Maintenance: Follow recommended maintenance practices provided by the coupling manufacturer to extend its lifespan and performance.

By addressing misalignment issues proactively and following proper maintenance practices, you can ensure the optimal performance and longevity of tooth couplings in your machinery systems.

Backlash in Tooth Couplings and Its Impact on Performance

Backlash is a crucial factor in tooth couplings that affects their performance. Backlash refers to the angular movement or play between the teeth of the coupling when there is a change in the direction of loading. It is the amount by which a tooth space exceeds the thickness of the engaged tooth.

The impact of backlash on performance includes:

- Positioning Accuracy: Backlash can lead to positioning inaccuracies in systems where precise motion control is required. As the direction of loading changes, the teeth need to engage before transmitting torque, causing a delay and affecting accuracy.

- Reversal Shock: In systems with frequent changes in direction, backlash can result in a sudden impact or shock when the teeth engage, leading to vibrations and potential damage to the coupling and connected components.

- System Response: Backlash can introduce a dead zone or delay in the system response when the loading direction changes. This can affect the system’s ability to respond quickly to changes in input.

- Reduced Efficiency: Backlash causes energy loss due to the need to overcome the play between teeth during direction changes. This can reduce the overall efficiency of the system.

- Wear and Fatigue: Backlash can lead to wear and fatigue of the coupling teeth and other components due to repeated impacts during loading changes.

- Noise and Vibration: The sudden engagement of teeth can generate noise and vibration, affecting the overall smoothness of operation and potentially leading to fatigue failure.

Minimizing backlash is important for improving the performance of tooth couplings. Some couplings are designed with features to reduce or compensate for backlash, while others require precise alignment and regular maintenance to manage backlash within acceptable limits.

Factors for Selecting a Tooth Coupling

When choosing a tooth coupling for a specific application, consider the following factors:

- Load and Torque: Determine the maximum load and torque requirements of the application to ensure the coupling can handle the expected forces.

- Speed: Consider the rotational speed of the equipment as higher speeds may require specialized couplings with enhanced balance and accuracy.

- Alignment Tolerance: Evaluate the degree of misalignment the coupling can accommodate without affecting performance.

- Environment: Assess the operating environment, including temperature, humidity, and exposure to contaminants or corrosive substances.

- Size and Space: Choose a coupling size that fits within the available space and meets the connection requirements of the shafts.

- Backlash: Determine the acceptable level of backlash, as some applications may require minimal or zero backlash for precise motion.

- Shock and Vibration: Consider whether the application involves frequent shocks or vibrations and choose a coupling that can dampen these effects.

- Material: Select the appropriate coupling material based on factors like corrosion resistance, strength, and compatibility with the connected components.

- Maintenance: Evaluate the ease of maintenance, including access to lubrication points and the need for periodic inspection and replacement.

- Cost: Balance the performance requirements with the budget constraints of the project.

Considering these factors will help you choose the right tooth coupling for your specific application, ensuring optimal performance and reliability.

editor by CX 2023-10-19

China Custom Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc Curved Tooth Flex Rigid Drive Shaft Nm Yox Fluid Jaw Flexible Chain Gear Couplings

Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer’s requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don’t even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Comparison of Tooth Couplings with Gear and Jaw Couplings

Tooth couplings, gear couplings, and jaw couplings are all types of couplings used in mechanical systems. Here’s a comparison of tooth couplings with gear and jaw couplings:

Tooth Couplings:

- They have interlocking teeth that provide high torque transmission capacity.

- Offer excellent misalignment compensation due to the tooth design.

- Can handle angular, radial, and axial misalignment.

- Transmit torque with low backlash and high torsional stiffness.

Gear Couplings:

- Use gears to transmit torque, providing high torque capacity.

- Handle angular misalignment but are less effective with radial and axial misalignment.

- Have backlash due to the gear design, which can affect precision applications.

- Require periodic lubrication and maintenance.

Jaw Couplings:

- Use elastomeric elements (jaws) for torque transmission.

- Provide good torsional stiffness and misalignment compensation.

- Handle moderate angular and axial misalignment but limited radial misalignment.

- Are simple in design and easy to install.

Ultimately, the choice between these couplings depends on the specific requirements of the application. Tooth couplings are preferred for high torque, precision, and demanding applications that require precise torque transmission and efficient misalignment compensation. Gear couplings excel in high torque situations but may have more backlash. Jaw couplings are suitable for simpler applications with moderate misalignment and torque requirements.

Suitability of Tooth Couplings for High-Speed Rotation and Heavy Loads

Yes, tooth couplings are well-suited for applications that involve high-speed rotation and heavy loads. Here’s why:

High-Speed Rotation: Tooth couplings are designed to transmit torque efficiently even at high rotational speeds. The tooth engagement provides a reliable means of torque transmission without slippage, making them ideal for high-speed applications.

Heavy Loads: Tooth couplings are robust and capable of handling substantial loads due to the interlocking teeth design. The teeth provide a secure connection that can transmit high levels of torque without deformation or damage.

Accuracy and Precision: Tooth couplings offer precise and accurate torque transmission, making them suitable for applications where precise positioning or synchronization is essential.

Minimal Backlash: Tooth couplings generally have minimal backlash due to the tight meshing of teeth. This reduces the play between the connected shafts, ensuring consistent motion and accurate positioning.

Sturdiness: Tooth couplings are manufactured from durable materials, making them capable of withstanding the stresses and forces associated with heavy loads and high speeds.

Customization: Tooth couplings can be tailored to specific applications by adjusting parameters such as tooth profile, size, and materials. This allows engineers to optimize the coupling’s performance for the intended use.

Advanced Designs: Modern tooth coupling designs incorporate advanced engineering techniques, such as finite element analysis, to ensure optimal performance even under challenging conditions.

Overall, tooth couplings offer a reliable solution for applications that demand both high-speed rotation and the ability to handle heavy loads effectively.

Benefits and Applications of Tooth Couplings

Using a tooth coupling offers several key benefits in mechanical systems:

- High Torque Transmission: Tooth couplings can handle high torque loads, making them suitable for heavy-duty applications.

- Angular Misalignment: They accommodate angular misalignment between shafts, reducing stress and wear on components.

- Axial Movement: Tooth couplings allow limited axial movement, which is crucial in applications with varying distances between shafts.

- Compact Design: Tooth couplings have a compact design, making them ideal for applications with limited space.

- Efficient Power Transmission: The meshing teeth provide efficient torque transmission with minimal backlash.

Tooth couplings find applications in various industries:

- Manufacturing: Used in conveyor systems, pumps, compressors, and machine tools.

- Automotive: Used in drivetrains, power transmission, and steering systems.

- Marine: Used in marine propulsion systems, winches, and deck machinery.

- Power Generation: Used in turbines, generators, and cooling tower fans.

- Aerospace: Used in aircraft control systems, landing gear, and engine accessories.

editor by CX 2023-10-07

China best High Quality Steel Tooth Flexible Rubber Plastic Falk Flexible Nylon Sleeve Universal Joints Chainbox Muff Gear Coupling Replacement of Bowex Coupling

Product Description

High Quality Steel Tooth Flexible Rubber Plastic Falk Flexible Nylon Sleeve Universal Joints Chainbox Muff Gear Coupling Replacement of Bowex Coupling

A gear coupling is a type of mechanical coupling that is used to connect 2 shafts at their ends to transmit torque and rotational motion. It consists of 2 hubs with external teeth connected by a flexible element, typically a sleeve or a disk, with internal teeth.

The hubs are usually made of steel or other high-strength materials, and the teeth are cut using precision machining techniques to ensure proper fit and alignment. The flexible element is designed to compensate for any misalignment between the 2 shafts and to allow for a slight amount of angular and axial misalignment during operation.

Gear couplings are commonly used in heavy-duty applications, such as in large machinery and industrial equipment, where high torque and precision are required. They are also used in applications where shafts are subjected to significant amounts of vibration and shock, such as in marine and aerospace applications.

One of the advantages of gear couplings is that they are highly efficient at transmitting torque, with very little energy loss. They are also durable and require minimal maintenance, making them popular in many industries.

Materials Used in Manufacturing Tooth Couplings

Common materials used in manufacturing tooth couplings include:

- Steel: Steel is a popular choice due to its high strength and durability. It can handle heavy loads and is suitable for a wide range of applications.

- Cast Iron: Cast iron is known for its excellent wear resistance and ability to dampen vibrations. It is often used in applications where shock absorption is important.

- Stainless Steel: Stainless steel is corrosion-resistant and can withstand harsh environments, making it suitable for industries like food processing and marine applications.

- Aluminum: Aluminum is lightweight and offers good corrosion resistance. It’s commonly used in applications where weight reduction is important.

- Bronze: Bronze is used for its self-lubricating properties and resistance to corrosion. It’s often employed in applications where lubrication is challenging.

The choice of material depends on factors such as the specific application, operating conditions, and required performance characteristics. Engineers select materials that offer the best combination of strength, durability, corrosion resistance, and other properties needed for the intended use of the tooth coupling.

Influence of Teeth Profiles and Spacing on Tooth Coupling Performance

The design of teeth profiles and spacing in tooth couplings significantly impacts their performance in various ways:

1. Torque Transmission: The shape of teeth profiles determines how efficiently torque is transmitted between the two shafts. Properly designed profiles maximize the surface contact area, enhancing torque transmission capabilities.

2. Load Distribution: The teeth profiles and spacing affect how loads are distributed across the coupling. Even distribution helps prevent localized stress concentrations and ensures uniform wear and longevity.

3. Misalignment Compensation: Tooth couplings with specific teeth profiles and spacing can better accommodate angular, radial, and axial misalignments between shafts. This reduces the risk of excessive wear and prolongs coupling life.

4. Backlash and Precision: The teeth spacing impacts the level of backlash, or play, between the teeth during rotation. Smaller teeth spacing reduces backlash, leading to more precise and accurate motion transmission.

5. Noise and Vibration: Well-designed teeth profiles and spacing can minimize noise and vibration during operation by promoting smoother engagement and disengagement of teeth.

6. Fatigue Resistance: Proper teeth profiles and spacing help distribute stresses evenly, enhancing the coupling’s fatigue resistance against cyclic loads.

7. Material Selection: Teeth profiles and spacing also influence the choice of materials for the coupling. Certain profiles may require specific materials to ensure durability and optimal performance.

8. Efficiency: Optimized teeth profiles and spacing reduce friction and wear, resulting in higher coupling efficiency and less energy loss.

9. Customization: The flexibility to customize teeth profiles and spacing allows engineers to tailor the coupling’s performance to the specific application requirements.

Overall, the design of teeth profiles and spacing is a critical factor in determining the overall efficiency, durability, precision, and performance of tooth couplings in various mechanical systems.

Proper Installation and Maintenance of Tooth Couplings

To ensure the proper function and longevity of a tooth coupling, follow these guidelines:

Installation:

- Ensure shafts are aligned within manufacturer specifications to prevent excessive loads on the coupling.

- Clean and inspect the coupling components before installation to avoid debris or contaminants.

- Use appropriate tools and methods to achieve proper fit between the coupling and the shafts.

- Follow the manufacturer’s instructions for tightening bolts or fasteners to the recommended torque.

Maintenance:

- Regularly inspect the coupling for signs of wear, such as tooth damage, corrosion, or misalignment.

- Check for any abnormal vibrations, noise, or overheating during operation, which could indicate coupling issues.

- Keep the coupling and surrounding area clean to prevent the accumulation of dirt or debris.

- Regularly lubricate the coupling as per the manufacturer’s recommendations to reduce friction and wear.

- Monitor the alignment of the connected equipment and address any misalignment promptly.

- Replace worn or damaged components promptly to avoid further damage and maintain coupling performance.

Following proper installation and maintenance practices will help maximize the efficiency and service life of the tooth coupling.

editor by CX 2023-09-28

China Good quality Flexible Drum Curved Tooth Gear Coupling with High Quality

Product Description

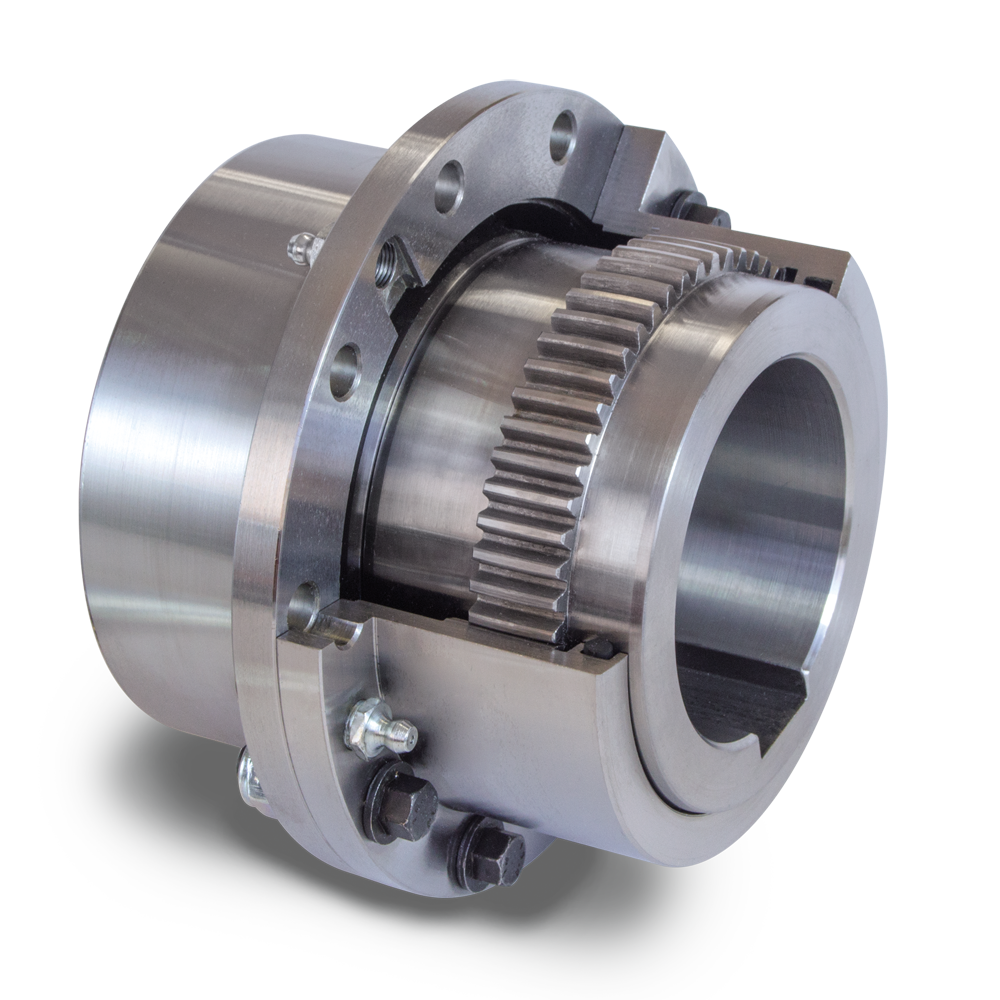

Drum Gear Coupling Shaft Coupling (GIICL)

GIICL type – the sealing end for the entire body, small spacing between the teeth, the relative allowable radial displacement, compact structure, small moment of inertia, can be connected with the Y, J1 type shaft.

Characteristics of drum type gear coupling:

1.drum tooth type coupling bearing capacity

2.angular displacement compensation

3.drumgear coupling drum tooth surface contact condition of inner and outer teeth are improved, to avoid the angular displacement under the condition of straight tooth end edge extrusion, stress measuringmethods concentration, while improving the tooth surface friction, wear, reducing noise and long maintenance cycle.

4.drum shaped teeth type shaft coupling gear tooth end is CHINAMFG shape, so that the inner and outer teeth are very convenient to install and remove.

5.drum gear type coupling transmission efficiency as high as 99.7%.

<table border="0" cellpadding="/8822 0571 1.75

Detailed Photos

Company Profile

HangZhou CHINAMFG Machinery Manufacturing Co., Ltd. is a high-tech enterprise specializing in the design and manufacture of various types of coupling. There are 86 employees in our company, including 2 senior engineers and no fewer than 20 mechanical design and manufacture, heat treatment, welding, and other professionals.

Advanced and reasonable process, complete detection means. Our company actively introduces foreign advanced technology and equipment, on the basis of the condition, we make full use of the advantage and do more research and innovation. Strict to high quality and operate strictly in accordance with the ISO9000 quality certification system standard mode.

Our company supplies different kinds of products. High quality and reasonable price. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective.

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and TS16949.

FAQ

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing

various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all customers with customized PDF or AI format artwork.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: Do you provide samples? Is it free or extra?

Yes, we could offer the sample but not for free. Actually, we have an excellent price principle, when you make the bulk order the cost of the sample will be deducted.

Q 5: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 6: What is the MOQ?

A: Usually our MOQ is 1pcs.

Q 7: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 8: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

Q 9: What’s your payment?

A:1) T/T.

♦Contact Us

Web: huadingcoupling

Add: No.11 HangZhou Road,Chengnan park,HangZhou City,ZheJiang Province,China

Misaligned Tooth Couplings: Challenges and Mitigation

Misalignment in tooth couplings can lead to various challenges that affect coupling performance and equipment reliability. Here are some challenges that can arise from misaligned tooth couplings and how they can be mitigated:

1. Increased Wear: Misalignment causes uneven loading and increased stress on the teeth of the coupling, leading to accelerated wear and potential tooth damage.

2. Reduced Efficiency: Misaligned couplings can result in energy losses due to increased friction and inefficient torque transmission.

3. Vibration and Noise: Misalignment can induce vibration and noise in the machinery system, affecting both operator comfort and equipment lifespan.

4. Premature Failure: Excessive misalignment can lead to premature coupling failure and unexpected downtime.

To mitigate these challenges, consider the following steps:

1. Proper Alignment: Ensure that the connected shafts are aligned within the specified tolerances. Use alignment tools and techniques to achieve accurate shaft alignment.

2. Regular Inspection: Perform routine inspections of the coupling to detect any signs of wear, damage, or misalignment. Address any issues promptly.

3. Lubrication: Proper lubrication reduces friction and wear, especially in misaligned conditions. Follow manufacturer guidelines for lubrication frequency and type.

4. Coupling Maintenance: Follow recommended maintenance practices provided by the coupling manufacturer to extend its lifespan and performance.

By addressing misalignment issues proactively and following proper maintenance practices, you can ensure the optimal performance and longevity of tooth couplings in your machinery systems.

Identifying Wear or Damage in Tooth Couplings

Wear or damage in a tooth coupling can lead to performance issues and potential failures. Here are some signs to watch for and methods to identify problems:

- Abnormal Noise: Unusual noise during operation, such as rattling, grinding, or clicking, can indicate misalignment or wear in the teeth.

- Increased Vibration: Excessive vibration may suggest misalignment, worn teeth, or other issues affecting coupling performance.

- Temperature Rise: If the coupling becomes unusually hot during operation, it could indicate friction due to misalignment or damaged teeth.

- Visual Inspection: Regularly inspect the coupling for signs of wear, corrosion, pitting, or chipped teeth. Use proper lighting and magnification if needed.

- Measurement: Check tooth clearances using specialized measurement tools to identify any significant deviations from specifications.

- Runout Measurement: Measure coupling runout to detect eccentricity or misalignment that could lead to premature wear.

- Alignment Check: Use laser alignment tools to ensure proper shaft alignment, preventing undue stress on the coupling teeth.

- Lubrication Analysis: Analyze the lubricant for metal particles or signs of contamination, which could result from wear and damage.

Regular inspection, monitoring operating conditions, and addressing any signs of wear or damage promptly can help extend the life of the tooth coupling and prevent unexpected failures.

Types of Tooth Couplings for Specific Uses

There are various types of tooth couplings designed to cater to specific application requirements:

- Spur Tooth Couplings: These are the most common type, with straight teeth that transmit torque and handle misalignment.

- Helical Tooth Couplings: Helical teeth reduce noise, vibrations, and backlash while providing smooth torque transmission.

- Bevel Tooth Couplings: Ideal for applications where shafts intersect at an angle, such as in right-angle drives.

- Internal Tooth Couplings: Suitable for applications where space is limited and torque needs to be transmitted through the inside of the coupling.

- Sliding Tooth Couplings: These allow axial movement between shafts while transmitting torque, making them useful in applications with varying distances.

- Flexible Tooth Couplings: These accommodate misalignment and dampen vibrations, commonly used in pumps, compressors, and turbines.

The choice of tooth coupling type depends on factors like torque requirements, misalignment, space constraints, and specific application demands.

editor by CX 2023-09-21