Product Description

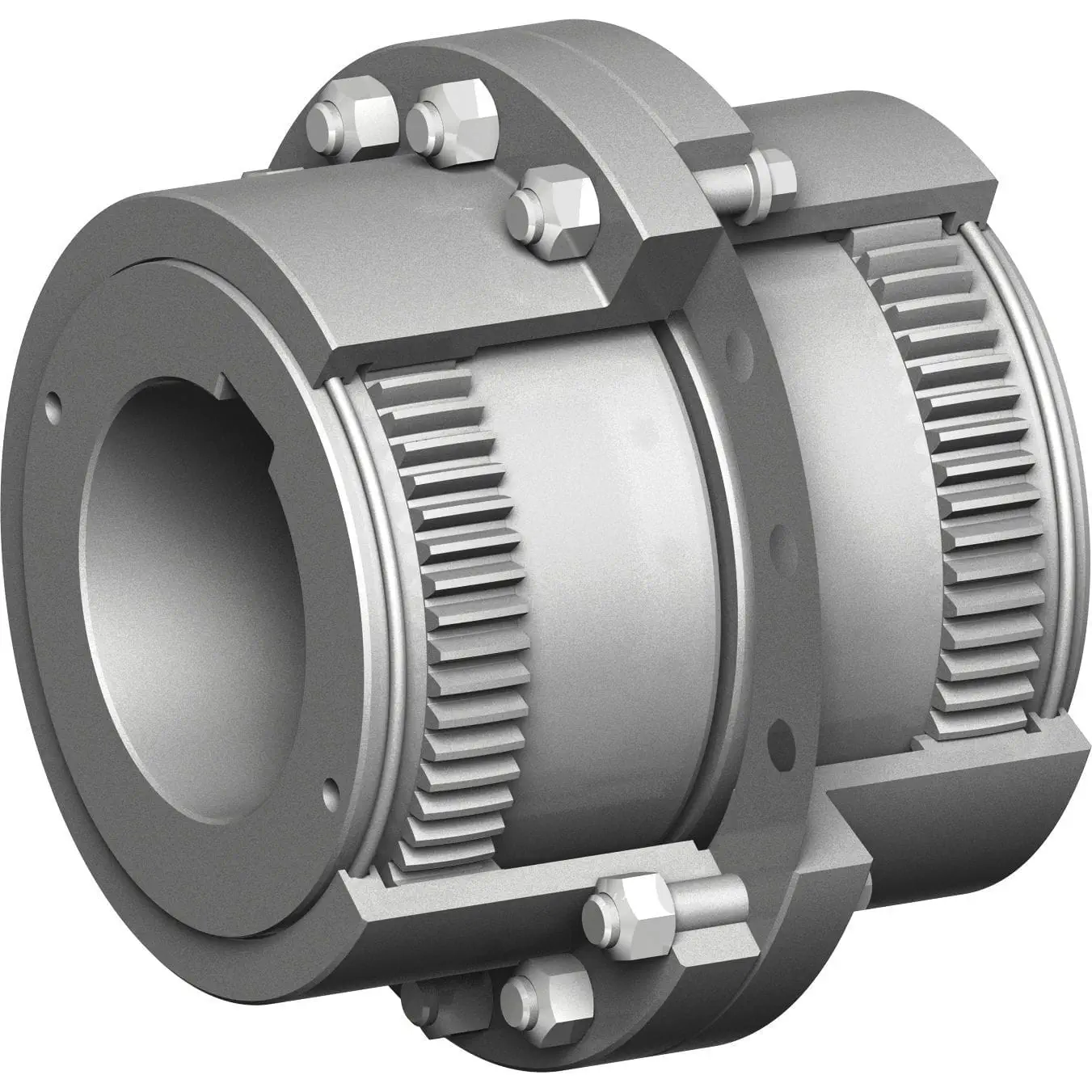

Flange Cast Iron Coupling Steel Universal Joint Cardan Pump Rubber Motor Disc CHINAMFG Flex Rigid Drive Shaft NM yox Fluid Jaw Flexible Chain Gear Couplings

Manufacturer of Couplings, Fluid Coupling, JAW Coupling, can interchange and replacement of lovejoy coupling and so on.

A coupling can interchange and replacement of lovejoy coupling is a device used to connect 2 shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join 2 pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

Coupling is a jaw type coupling that works for a variety of light duty to heavy duty motors used in electric power transmission.

This is 1 of our safest types of products. The reason being that these couplings work even when the elastomer fails and there is no metal to metal contact.

They perform in well-standing oil, grease, moisture, sand, and dirt and nearly 850,000 bore combinations that can be customised as per the customer’s needs.

They are used in light-weight, medium, or heavy electrical motors and devices for power transmission through internal combustion.

Production workshop:

Company information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Misaligned Tooth Couplings: Challenges and Mitigation

Misalignment in tooth couplings can lead to various challenges that affect coupling performance and equipment reliability. Here are some challenges that can arise from misaligned tooth couplings and how they can be mitigated:

1. Increased Wear: Misalignment causes uneven loading and increased stress on the teeth of the coupling, leading to accelerated wear and potential tooth damage.

2. Reduced Efficiency: Misaligned couplings can result in energy losses due to increased friction and inefficient torque transmission.

3. Vibration and Noise: Misalignment can induce vibration and noise in the machinery system, affecting both operator comfort and equipment lifespan.

4. Premature Failure: Excessive misalignment can lead to premature coupling failure and unexpected downtime.

To mitigate these challenges, consider the following steps:

1. Proper Alignment: Ensure that the connected shafts are aligned within the specified tolerances. Use alignment tools and techniques to achieve accurate shaft alignment.

2. Regular Inspection: Perform routine inspections of the coupling to detect any signs of wear, damage, or misalignment. Address any issues promptly.

3. Lubrication: Proper lubrication reduces friction and wear, especially in misaligned conditions. Follow manufacturer guidelines for lubrication frequency and type.

4. Coupling Maintenance: Follow recommended maintenance practices provided by the coupling manufacturer to extend its lifespan and performance.

By addressing misalignment issues proactively and following proper maintenance practices, you can ensure the optimal performance and longevity of tooth couplings in your machinery systems.

Specialized Maintenance Practices for Longevity of Tooth Couplings

To ensure the longevity of tooth couplings, specialized maintenance practices should be followed:

- Lubrication: Proper lubrication is crucial to reduce friction and wear between the teeth. Use lubricants recommended by the coupling manufacturer and ensure regular lubrication.

- Lubricant Quality: Use high-quality lubricants with suitable viscosity and additives for optimal performance and protection against corrosion.

- Lubrication Frequency: Follow the manufacturer’s recommendations for lubrication intervals. Factors such as operating conditions and environment can influence the frequency.

- Alignment: Maintain proper alignment of connected shafts to prevent excessive load and wear on the teeth. Misalignment can lead to premature failure.

- Inspection: Regularly inspect tooth couplings for signs of wear, damage, or misalignment. Early detection allows for timely repairs or replacements.

- Torque Monitoring: Monitor transmitted torque to ensure it remains within the coupling’s rated capacity. Excessive torque can lead to overloading and damage.

- Temperature: Monitor coupling temperature during operation. Elevated temperatures could indicate problems like inadequate lubrication or misalignment.

- Vibration Analysis: Use vibration analysis tools to detect abnormal vibrations that may indicate coupling issues or misalignment.

- Professional Inspection: Periodically have a professional inspect and assess the condition of the tooth coupling. They can identify potential issues that might go unnoticed.

- Replace Worn Parts: If wear or damage is detected, replace worn components promptly to prevent further deterioration.

- Manufacturer Guidelines: Adhere to the manufacturer’s maintenance recommendations and guidelines for the specific tooth coupling model.

Following these specialized maintenance practices can help ensure the reliable operation and extended lifespan of tooth couplings in machinery systems.

Proper Installation and Maintenance of Tooth Couplings

To ensure the proper function and longevity of a tooth coupling, follow these guidelines:

Installation:

- Ensure shafts are aligned within manufacturer specifications to prevent excessive loads on the coupling.

- Clean and inspect the coupling components before installation to avoid debris or contaminants.

- Use appropriate tools and methods to achieve proper fit between the coupling and the shafts.

- Follow the manufacturer’s instructions for tightening bolts or fasteners to the recommended torque.

Maintenance:

- Regularly inspect the coupling for signs of wear, such as tooth damage, corrosion, or misalignment.

- Check for any abnormal vibrations, noise, or overheating during operation, which could indicate coupling issues.

- Keep the coupling and surrounding area clean to prevent the accumulation of dirt or debris.

- Regularly lubricate the coupling as per the manufacturer’s recommendations to reduce friction and wear.

- Monitor the alignment of the connected equipment and address any misalignment promptly.

- Replace worn or damaged components promptly to avoid further damage and maintain coupling performance.

Following proper installation and maintenance practices will help maximize the efficiency and service life of the tooth coupling.

editor by CX 2024-05-09

by

Tags:

Leave a Reply