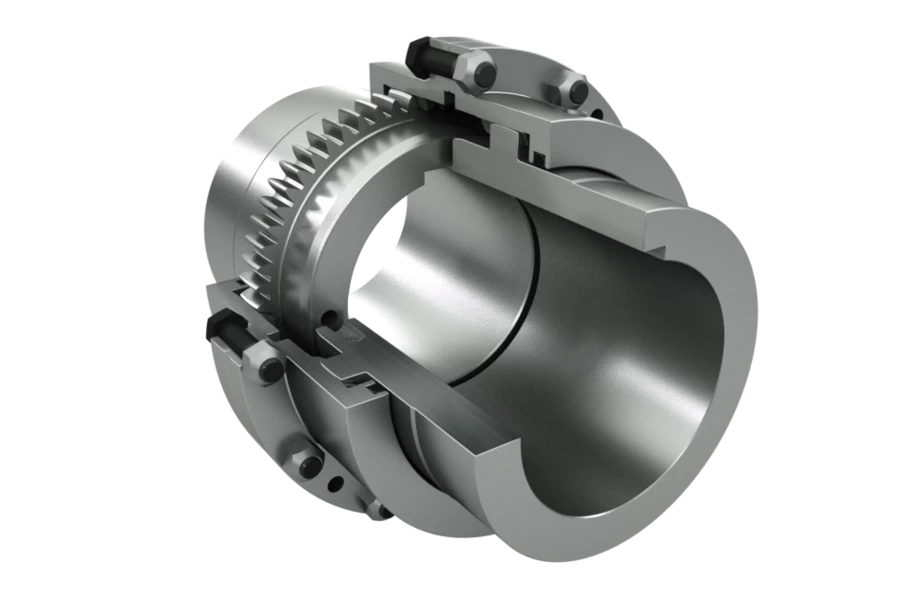

Product Description

|

Material |

20CrMn5,20CrMnTi,40Cr,Powder deposit,45#steel,42CrMo,Stainless steel and so on as per your requests. |

|||

|

Custom |

OEM/ODM |

|||

|

Lead Time |

Sample: 20-30 days after deposit received, Batch goods: 30-45days after samples have been approved. Die opening product:7-15days after samples have been approved.It takes 45-60 days to open the mold. |

|||

|

Processing |

Forging,Machining,Hobbing,Milling,Shaving,Grinding teeth, inserting teeth, shot blasting, Grinding,Heat treatment…… |

|||

|

Heat Treatment |

Intermediate frequency, high frequency, tempering, desalinating, carburizing…… |

|||

|

Main Machines |

CNC gear hobbing machine, CNC gear cutting machine, CNC lathe, CNC gear shaving machine, CNC gear milling machine, CNC gear grinding machine, CNC Grinding Machine…. |

|||

CHINAMFG has been engaged in manufacturing of forgings, castings, heat treatment and CNC machining parts since 1999.

The products materials have passed EN15714-3.1 certification, covering various grades of: low carbon steel, alloy steel, stainless steel, ductile iron, aluminum alloy, copper alloy, titanium alloy.

The main processes are: free forging, die forging, rolling ring, high pressure casting, centrifugal casting, normalizing, quenching and tempering, solution treatment, aging treatment, carbonitriding, turning, milling, drilling, grinding, hobbing, high frequency quenching, galvanizing, chrome plating, anodizing, powder spraying and other processes.

Rings and plates dimensions: Max 3000mm, shafts length: Max 12000mm, single piece weight: Max 16 Tons, at the same time we are good at terminal machining of complex products, dimension accuracy: Min 0.01mm, roughness: Min Ra0.6.

Products can be strictly examined by chemical composition, tensile strength, yield strength, reduction of area, impact at low temperature, intergranular corrosion, hardness, metallographic, NDT, size, static balance etc performance parameter.

Products are widely used in: aerospace, ships, trains, automobiles, engineering vehicles, chemical industry and petroleum refining, wellheads, x-mas tree equipment, mining machinery, food machinery, hydraulic and wind power generation, new energy equipment etc field.

Welcome to send: PDF, IGS, STP and other format drawings, of course we could also make material judgment and size survey according to your samples.

With more than 20 years of manufacturing experience and overseas sales team, we have achieved 100% customer satisfaction. The warranty period of products sold is 365 days. We look CHINAMFG to your consultation and cooperation at any time and common prosperity development.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Tooth Couplings

There are industry standards and guidelines that govern the design and use of tooth couplings. Some of these include:

- AGMA 9002-A94: This standard provides information on the selection and application of flexible couplings, including tooth couplings.

- ISO 14691: This international standard specifies methods for calculating the load capacity of tooth couplings.

- DIN 740: This German standard provides information on dimensions and requirements for tooth couplings.

- API 671: This American Petroleum Institute (API) standard specifies requirements for special purpose couplings, including tooth couplings, for use in the petroleum and natural gas industries.

These standards provide guidelines for the design, selection, installation, and maintenance of tooth couplings to ensure safe and reliable operation. Engineers and designers often refer to these standards to ensure that tooth couplings are used appropriately in various applications.

Influence of Teeth Profiles and Spacing on Tooth Coupling Performance

The design of teeth profiles and spacing in tooth couplings significantly impacts their performance in various ways:

1. Torque Transmission: The shape of teeth profiles determines how efficiently torque is transmitted between the two shafts. Properly designed profiles maximize the surface contact area, enhancing torque transmission capabilities.

2. Load Distribution: The teeth profiles and spacing affect how loads are distributed across the coupling. Even distribution helps prevent localized stress concentrations and ensures uniform wear and longevity.

3. Misalignment Compensation: Tooth couplings with specific teeth profiles and spacing can better accommodate angular, radial, and axial misalignments between shafts. This reduces the risk of excessive wear and prolongs coupling life.

4. Backlash and Precision: The teeth spacing impacts the level of backlash, or play, between the teeth during rotation. Smaller teeth spacing reduces backlash, leading to more precise and accurate motion transmission.

5. Noise and Vibration: Well-designed teeth profiles and spacing can minimize noise and vibration during operation by promoting smoother engagement and disengagement of teeth.

6. Fatigue Resistance: Proper teeth profiles and spacing help distribute stresses evenly, enhancing the coupling’s fatigue resistance against cyclic loads.

7. Material Selection: Teeth profiles and spacing also influence the choice of materials for the coupling. Certain profiles may require specific materials to ensure durability and optimal performance.

8. Efficiency: Optimized teeth profiles and spacing reduce friction and wear, resulting in higher coupling efficiency and less energy loss.

9. Customization: The flexibility to customize teeth profiles and spacing allows engineers to tailor the coupling’s performance to the specific application requirements.

Overall, the design of teeth profiles and spacing is a critical factor in determining the overall efficiency, durability, precision, and performance of tooth couplings in various mechanical systems.

Benefits and Applications of Tooth Couplings

Using a tooth coupling offers several key benefits in mechanical systems:

- High Torque Transmission: Tooth couplings can handle high torque loads, making them suitable for heavy-duty applications.

- Angular Misalignment: They accommodate angular misalignment between shafts, reducing stress and wear on components.

- Axial Movement: Tooth couplings allow limited axial movement, which is crucial in applications with varying distances between shafts.

- Compact Design: Tooth couplings have a compact design, making them ideal for applications with limited space.

- Efficient Power Transmission: The meshing teeth provide efficient torque transmission with minimal backlash.

Tooth couplings find applications in various industries:

- Manufacturing: Used in conveyor systems, pumps, compressors, and machine tools.

- Automotive: Used in drivetrains, power transmission, and steering systems.

- Marine: Used in marine propulsion systems, winches, and deck machinery.

- Power Generation: Used in turbines, generators, and cooling tower fans.

- Aerospace: Used in aircraft control systems, landing gear, and engine accessories.

editor by CX 2024-04-24

by

Tags:

Leave a Reply