Product Description

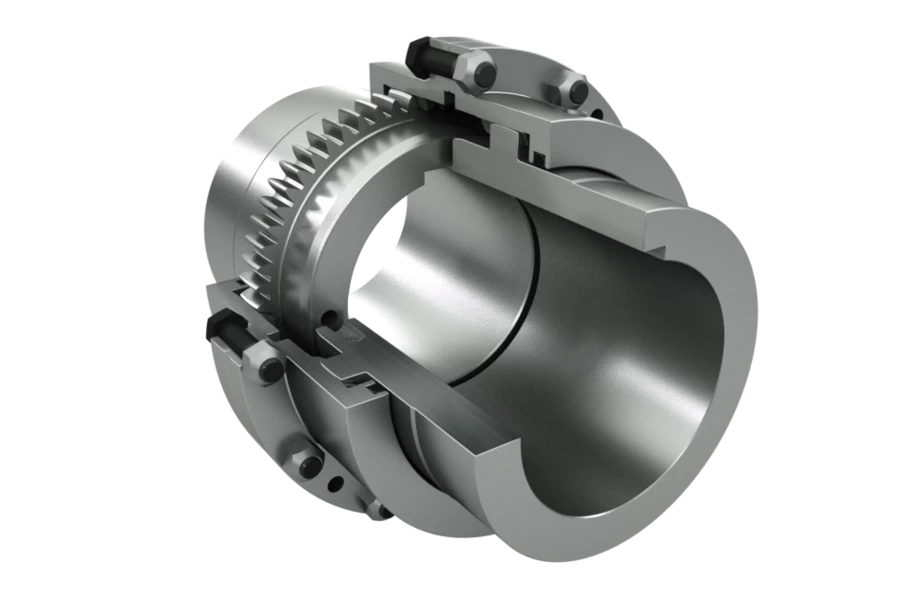

SG7-ZL/ZLD Type China Factory Pin Tooth Flexible Gear Coupling

Product Description

Features

1.Huge torsion of transmission,small size,light weight

2.No need librations,easy to maintain

Material:Carbon Steel

Application:Suitable for medium and large power shaft transmission

Remark

1.The coupling approximation is the driving moment of inertia and weight

2.Bore dimensions can be customized

Drawing of SG7-ZL/ZLD Type China Factory Pin Tooth Flexible Gear Coupling

Packaging & Shipping

| Packaging Detail: | Plastic Bag + Standard Color Box + Carton |

| Delivery Detail: | 15-30 days(It is up to your order) |

| Shipment: | DHL / Fedex / UPS etc. |

Our Services

| Design ideas | ||||||||||

| Shang Kun industrial hardware is a professional factory for hinge and latch, the quality of our product is very good and the price is reasonable, the entire products design aesthetic generous, With our own R&D team and strong ability of material sourcing, we are always competent for most of requirement from customers. We have established a strict quality control system in factory, so,it is the perfect goods for your choice. | ||||||||||

| Quality Control | ||||||||||

| All the material is provided by specialized supplies. so we do not cut corners, the weight is natural, and the hinge’s working life is very long, so it has a good value. We can provide many kinds of different material quality series products for your chose. | ||||||||||

| Service | ||||||||||

| *Customized logo: Acceptable | ||||||||||

| *Changing on material, mould, shape: Acceptable | ||||||||||

| *Develop on Artwork and Sketch: Acceptable | ||||||||||

| *Packing: Acceptable | ||||||||||

| *Sample: Acceptable | ||||||||||

| MOQ | ||||||||||

| Kindly, as to the smallest volume of order, we welcome buyers different size at least, at this stage and thus currently we have no strict limit on MOQ. | ||||||||||

| Payment | ||||||||||

| We accept many types of payment terms, such as TT, Paypal, Western Union, etc. Just according to your requirment. |

Company Information

FAQ

FAQ

1.Manufacturer supply:Direct production.There are inventory,fast delivery,quality assured!

2.About the size:all kinds of specification complete varieties.

3.About the color:according to your requirements.

4.About the services:24 hours,provide you with the latest prodect information and services.

5.About the after sale services:24 hours online provide service for you.

6.About the shipments:we have in stock,will delivery for you as soon as possible.

Related Products

Contact

Feel free to contact us!

| HangZhou Shangkun Industrial Technology Co.,LTD |

| Address: No.39, Shi Chang Road ,Zhuan Yao Industrial Area, Xihu (West Lake) Dis.Cheng District, Xihu (West Lake) Dis.Guan, ZheJiang , China |

| Attn: Alaia |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Tooth Couplings

There are industry standards and guidelines that govern the design and use of tooth couplings. Some of these include:

- AGMA 9002-A94: This standard provides information on the selection and application of flexible couplings, including tooth couplings.

- ISO 14691: This international standard specifies methods for calculating the load capacity of tooth couplings.

- DIN 740: This German standard provides information on dimensions and requirements for tooth couplings.

- API 671: This American Petroleum Institute (API) standard specifies requirements for special purpose couplings, including tooth couplings, for use in the petroleum and natural gas industries.

These standards provide guidelines for the design, selection, installation, and maintenance of tooth couplings to ensure safe and reliable operation. Engineers and designers often refer to these standards to ensure that tooth couplings are used appropriately in various applications.

Identifying Wear or Damage in Tooth Couplings

Wear or damage in a tooth coupling can lead to performance issues and potential failures. Here are some signs to watch for and methods to identify problems:

- Abnormal Noise: Unusual noise during operation, such as rattling, grinding, or clicking, can indicate misalignment or wear in the teeth.

- Increased Vibration: Excessive vibration may suggest misalignment, worn teeth, or other issues affecting coupling performance.

- Temperature Rise: If the coupling becomes unusually hot during operation, it could indicate friction due to misalignment or damaged teeth.

- Visual Inspection: Regularly inspect the coupling for signs of wear, corrosion, pitting, or chipped teeth. Use proper lighting and magnification if needed.

- Measurement: Check tooth clearances using specialized measurement tools to identify any significant deviations from specifications.

- Runout Measurement: Measure coupling runout to detect eccentricity or misalignment that could lead to premature wear.

- Alignment Check: Use laser alignment tools to ensure proper shaft alignment, preventing undue stress on the coupling teeth.

- Lubrication Analysis: Analyze the lubricant for metal particles or signs of contamination, which could result from wear and damage.

Regular inspection, monitoring operating conditions, and addressing any signs of wear or damage promptly can help extend the life of the tooth coupling and prevent unexpected failures.

Factors for Selecting a Tooth Coupling

When choosing a tooth coupling for a specific application, consider the following factors:

- Load and Torque: Determine the maximum load and torque requirements of the application to ensure the coupling can handle the expected forces.

- Speed: Consider the rotational speed of the equipment as higher speeds may require specialized couplings with enhanced balance and accuracy.

- Alignment Tolerance: Evaluate the degree of misalignment the coupling can accommodate without affecting performance.

- Environment: Assess the operating environment, including temperature, humidity, and exposure to contaminants or corrosive substances.

- Size and Space: Choose a coupling size that fits within the available space and meets the connection requirements of the shafts.

- Backlash: Determine the acceptable level of backlash, as some applications may require minimal or zero backlash for precise motion.

- Shock and Vibration: Consider whether the application involves frequent shocks or vibrations and choose a coupling that can dampen these effects.

- Material: Select the appropriate coupling material based on factors like corrosion resistance, strength, and compatibility with the connected components.

- Maintenance: Evaluate the ease of maintenance, including access to lubrication points and the need for periodic inspection and replacement.

- Cost: Balance the performance requirements with the budget constraints of the project.

Considering these factors will help you choose the right tooth coupling for your specific application, ensuring optimal performance and reliability.

editor by CX 2024-04-12

Leave a Reply