Hello, welcome to Cangzhou Ever-Power Co., Ltd.!

- Tyre coupling

- Flexible log-off coupling

- Flange coupling

- Universal coupling

- Roller sprocket coupling

- Drum type gear coupling

- Star elastic coupling

- Plum elastic coupling

- Oldham coupling

- Clamping coupling

- With brake disc coupling

- Snake-shaped yellow coupling

- Diaphragm coupling

- Nylon internal gear coupling

Contact Us

your present location:HOME > Diaphragm coupling > Snake-shaped yellow coupling >

Snake-shaped yellow coupling

JS serpentine spring coupling

Time: 2019-05-21 20:29 Author: admin Click:

JS serpentine spring coupling:

There are also retractable couplings suitable for servo motors required for ultra-precision control and engines that generate large vibrations and shocks. The product lineup is strong.

The high-rigidity metal leaf spring coupling is an ultra-high-rigidity metal leaf spring coupling developed for servo motors. This method has excellent properties of rigidity to torsion, eccentricity, deflection angle and axial displacement, using finite element method A thorough analysis of the leaf spring components, the pursuit of the ideal shape of the S-shaped serpentine spring coupling, the coupling is a kind of metal elastic coupling with advanced structure.It is transmitted by serpentine springs

Pass the torque.

Pass the torque.

The serpentine spring coupling realizes the connection between the driver and the driven machine through the serpentine springs axially embedded in the tooth grooves of the two halves of the coupling. During operation, the driven end is driven by the circumferential force of the driving end teeth facing the spring. Transmit torque.The contact point between the spring and the tooth profile changes with the torque, and the spring stiffness changes gradually. Therefore, the serpentine spring coupling is very suitable for occasions with large torque fluctuations and short shaft end distance.

The serpentine spring coupling has good vibration damping and long service life. The serpentine spring leaf axially embeds the two halves by more than 36%.The serpentine spring leaf of the trapezoidal section is made of spring steel, which has undergone strict heat treatment and special processing. It has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metal elastic element coupling (such as elastic sleeve column). Pins, nylon rod pin couplings) have greatly increased.

The transmission characteristics and advantages of the JS serpentine spring coupling are as follows:

1. The serpentine spring coupling has good vibration damping and long service life.The coupling is axially embedded in the two halves by a serpentine spring leaf for more than 36%.The serpentine spring coupling with trapezoidal section is made of spring steel, which has undergone strict heat treatment and special processing. It has good mechanical properties, so that the service life of the coupling is much longer than that of the non-metal elastic element coupling (such as elastic Set of pin, nylon rod pin coupling) greatly increased.

2. The serpentine spring coupling bears a large variable load range and is safe to start.The tooth surfaces of the two half couplings in contact with the reeds are curved. When the transmission torque increases, the springs will deform along the curved surfaces of the teeth, so that the force points of the two half couplings on the reeds are close.The contact point between the reed and the tooth surface, that is, the change of torque, changes with the size of the transmitted torque, and its transmission characteristics are variable stiffness.Therefore, it has a greater load variation than general elastic couplings.The buffering effect produced by the transmission force when the reed deforms along the tooth arc, especially when the machine is started or strong impact load, to a certain extent, protects the safety of the supporting parts.

3. The serpentine spring coupling has high transmission efficiency and reliable operation. The transmission efficiency of the coupling has been determined to reach 99.47%. Its short-term overload capacity is twice the rated torque, and its operation is safe and reliable.

4. The serpentine spring coupling has low noise. The aluminum alloy casing is lubricated to protect the spring from being thrown out during operation, and the shell is filled with butter, which not only makes the lubrication good, but also makes the noise when the reed is engaged. Damping is absorbed and eliminated.

5. The serpentine spring coupling has a simple structure and easy assembly and disassembly. The whole machine has few parts, small size and light weight. The spring leaf designed as a trapezoidal cross-section and the trapezoidal tooth groove are particularly convenient and close, so that the assembly and disassembly and maintenance It is simpler than general couplings.

6. The serpentine spring coupling allows greater installation deviation. Since the spring leaf and the tooth arc surface are in point contact, the coupling can obtain greater flexibility.It can be installed to work normally with radial, angular and axial deviations at the same time.

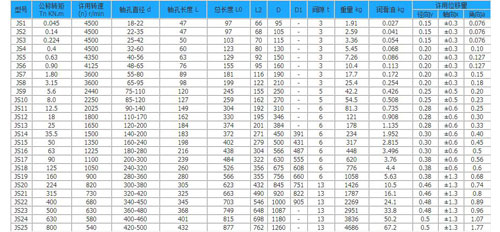

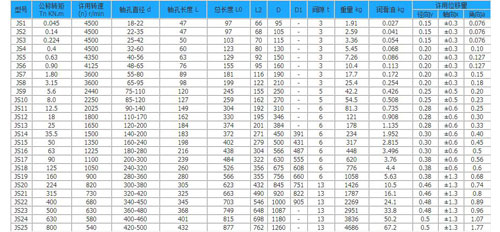

The basic dimensions and parameters of JS serpentine spring coupling

Previous:JSP type serpentine spring coupling with brake disc

Next:Nothing

Related Products: